Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-22

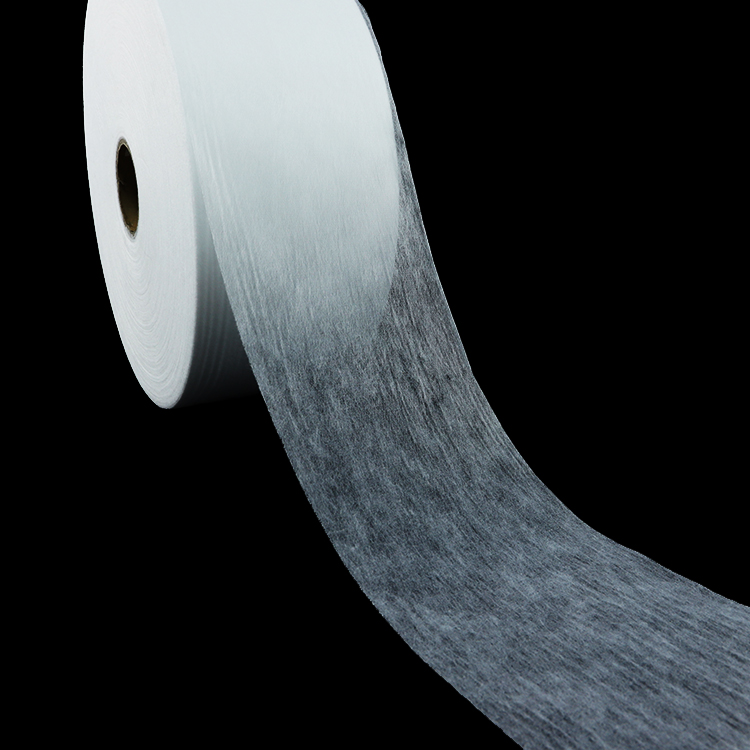

Thermal bond nonwoven fabric, also known as TBN fabric, has become an essential component in the manufacturing of diapers. Its versatile applications have revolutionized the diaper industry, offering superior performance and enhanced comfort for both infants and adults. This article explores the various ways in which thermal bond nonwoven fabric is used in diaper production, highlighting its benefits and impact on the overall quality of diapers.

One of the primary uses of thermal bond nonwoven fabric in diaper manufacturing is in the acquisition and distribution layer (ADL). This layer is responsible for quickly absorbing and distributing liquids, preventing leakage and keeping the skin dry. Thermal bond nonwoven fabric's excellent wicking properties enable it to rapidly absorb moisture and transport it away from the surface, ensuring that the diaper remains dry and comfortable. The uniform structure of the fabric allows for efficient liquid distribution, maximizing its absorption capacity.

Thermal bond nonwoven fabric is widely used in the fastening system of diapers. The fabric's high tensile strength and elasticity make it ideal for providing a secure and adjustable fit. It is used in the side panels and waistbands of diapers to ensure a snug yet comfortable fit around the baby's waist. The fabric's stretchability allows for easy adjustability, accommodating the baby's movements without causing discomfort or leaking. Furthermore, thermal bond nonwoven fabric's soft texture prevents skin irritation, making it suitable for prolonged use.

Diapers with thermal bond nonwoven fabric provide improved breathability and comfort for the wearer. The fabric's porous structure allows air to circulate freely, reducing the risk of skin irritation and rashes caused by excessive moisture and heat. It also helps in maintaining an optimal temperature within the diaper, preventing discomfort and diaper dermatitis. Thermal bond nonwoven fabric's lightweight and soft touch contribute to the overall comfort of the diaper, ensuring a pleasant experience for both babies and adults.

In summary, thermal bond nonwoven fabric plays a crucial role in the manufacturing of diapers, enhancing their performance and comfort. Its applications in the acquisition and distribution layer improve liquid absorption and distribution, preventing leakage and maintaining a dry surface. The fabric's strong fastening and elasticity properties enable a secure fit without compromising comfort. Additionally, its breathability and soft texture enhance comfort and reduce the risk of skin irritations. As the diaper industry continues to evolve, thermal bond nonwoven fabric remains an invaluable component, driving innovation and improving the lives of diaper wearers worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China