Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-22

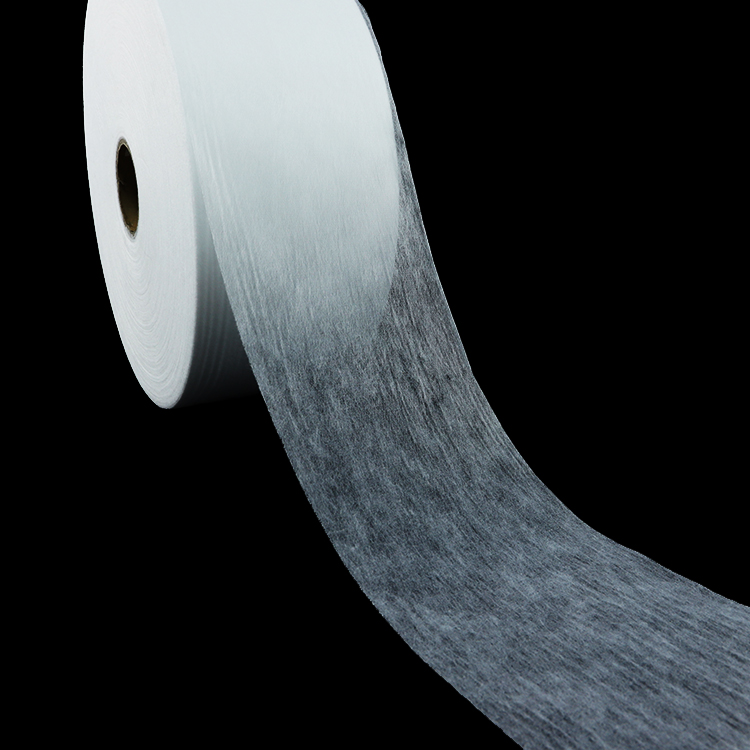

The versatile application of thermal bonded nonwoven in diapers has revolutionized the diaper industry by providing superior comfort, absorption, and leakage protection. Thermal bonded nonwovens are a type of fabric produced through a heat bonding process without the use of adhesives or stitching. This article explores the various uses and benefits of thermal bonded nonwoven in diapers.

One of the key advantages of using thermal bonded nonwoven in diapers is the enhanced comfort it provides to the wearer. The fabric is soft and gentle on the skin, reducing the risk of irritation and rashes. Unlike traditional stitched fabrics, thermal bonded nonwovens have a smooth surface that prevents chafing or rubbing against the baby's delicate skin. The lightweight and breathable nature of these nonwovens also allows for better air circulation, reducing the likelihood of excessive sweating and discomfort.

Thermal bonded nonwoven materials used in diapers offer exceptional absorption capabilities, ensuring the baby stays dry and comfortable for extended periods. These nonwovens are engineered with high-density fibers that can quickly absorb and distribute liquid evenly across the diaper. The absence of stitching or adhesives in the fabric eliminates the risk of leakage or sagging, providing a secure and snug fit. Moreover, thermal bonded nonwovens have the ability to retain moisture within their structure, preventing rewetting and maintaining dryness for prolonged use.

The tight bond created by the heat bonding process in thermal bonded nonwovens significantly enhances the leak protection in diapers. The absence of needle holes or loose threads reduces the chance of liquid passing through the fabric, minimizing the risk of leakage. The thermal bonding process also makes these nonwovens more durable, ensuring that they can withstand movement, stretching, and active play without compromising their protective properties. This improved leak protection not only keeps the baby dry but also prevents potential messes, providing peace of mind for parents and caregivers.

In conclusion, the versatile application of thermal bonded nonwoven in diapers has revolutionized the industry by providing enhanced comfort, absorption, and leak protection. The soft and breathable nature of these nonwovens enhances the comfort of the wearer, while their excellent absorption capabilities keep the baby dry for extended periods. Additionally, the tight bond and durability offered by thermal bonded nonwovens significantly reduce the risk of leaks. With these advantages, thermal bonded nonwoven has become an indispensable component in modern diaper manufacturing, ensuring the well-being and happiness of both babies and parents.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China