The spread of the new coronavirus around the world poses a huge threat to human life. Medical masks and protective clothing have become important protective equipment to prevent the spread of the virus and protect the health of people, and polypropylene meltblown non woven fabric has played a great role in it.

1. Development status of meltblown technology of polypropylene meltblown nonwoven fabric at home and abroad

As a nonwoven production process with an earlier origin, the meltblown process was successfully developed by the US Navy in the 1950s. Subsequently, American Exxo Company and AccurATe Company further researched the technology, and jointly produced the first polypropylene meltblown non-woven fabric unit. In the late 1970s, Exxo Company transferred the technology to civilian use. Major companies have carried out research and obtained patents based on this basis. For example, JMI Company in the United States has improved the conventional meltblown die head, and the die head replacement speed is accelerated by the die head parallel device, which saves the time of die head replacement in the production line; American BiAx Company in order to To improve production efficiency, the structure of multi-row spinneret holes in the melt-blown die head was developed; Japan Chisso Company first developed equipment for bi-component conjugate fiber melt-blown fiber web and sea-island fiber melt-blown fiber web; German LevenhAus-en Company The melt-blown die head is improved to make it high in production efficiency and excellent in product performance. As a result, meltblown non-woven fabrics have developed rapidly and become the second largest production method of non-woven fabrics.

Domestic research on meltblown technology began as early as the late 1950s. In the early 1990s, nearly 100 meltblown dies designed by Beijing Institute of Chemical Technology and China Textile University were produced in China. Then, Anhui Aohong and other enterprises successively introduced 5 continuous meltblown production lines, which opened up a new situation in my country's meltblown market. At that time, the main domestic application fields were battery separators, oil-absorbing materials, filter materials, etc., but due to market constraints, the development was slow. In the past ten years, with the development of economy and technology and the enhancement of environmental protection awareness, my country's meltblown technology has developed rapidly, and meltblown production equipment has been fully localized.

2. Characteristics of polypropylene meltblown non woven fabric

Isotactic polypropylene fiber has excellent properties such as abundant raw materials, high strength, light weight, good chemical resistance, resistance to insects and molds, and less contamination and pollution. The fibers in polypropylene meltblown non-woven fabrics are irregularly arranged and disordered. This structure makes the specific surface area larger and the pore size smaller, so it has better filterability and dust holding capacity than other non-woven fabrics, and is widely used in filter materials. The non-woven fabric contains a large number of fine pores and excellent lipophilicity, which makes it widely used in the field of oil-absorbing materials. In addition, due to its excellent reprocessing performance, its application fields are becoming more and more extensive, such as medical protection, sound insulation materials, thermal insulation materials, battery separators, etc.

3. Application of polypropylene meltblown non woven fabric

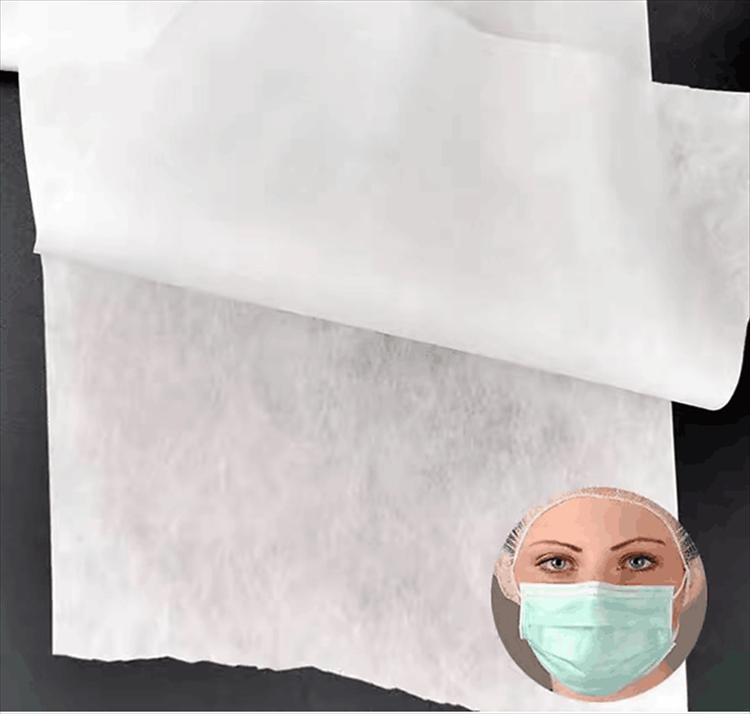

a. Medical protection

Medical protection is one of its main application areas. As people have higher requirements for health protection, its status in the medical and health field is increasing day by day. In recent years, polypropylene meltblown non-woven fabrics and spunbond non-woven fabrics have been compounded, which have the characteristics of high strength, good hand feeling, high efficiency and low resistance.

b. Thermal material

Polypropylene fiber has a large specific surface area, small pore size and high porosity. The fiber structure can store a large amount of air, effectively prevent heat loss, and has good thermal insulation and breathability.

c. Oil absorbing material

It has the chemical properties of good lipophilicity, poor hygroscopicity, and insoluble in oil and strong acid and alkali. It is a new type of oil-absorbing material with high efficiency and no pollution. Light weight, after oil absorption, it can still float on the water surface for a long time without deformation; it is a non-polar material, its oil absorption can reach dozens of times its own weight; non-toxic, good water and oil replacement, can be used repeatedly.

d. filter material

Filter material is its earliest application field, and its fiber diameter is less than 5μm, which is very suitable for use as air filter material. In particular, the electro-electret-treated meltblown material has the characteristics of fluffy structure, large porosity, large dust holding capacity, small breathing resistance and high filtration efficiency.

As an important material, polypropylene meltblown non woven fabric have good market prospects, and it is necessary to continue to increase research and development efforts to improve performance and reduce costs.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366 Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China