Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-03

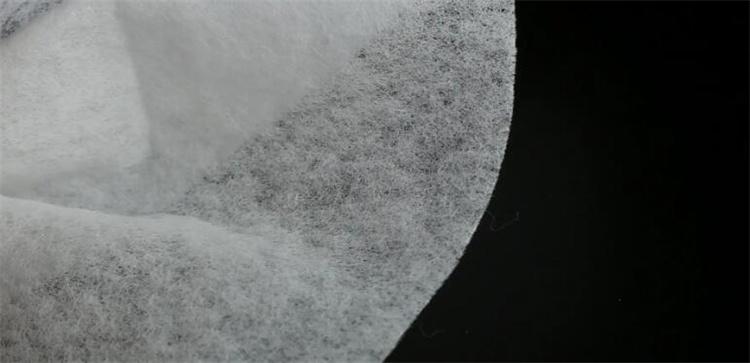

With the continuous improvement of people's quality of life and living standards, disposable hygiene products have become an important product in people's lives. Among them, diapers are widely used in infant care and elderly care. The traditional diapers have poor performance and cannot meet people's needs for nursing work, which affects the overall quality and effect of nursing care. In recent years, with the application of non-woven fabrics in diapers, the overall quality and performance of diapers have been greatly improved. The application of hydrophobic air through non woven fabric in diapers has also received great attention. This paper looks forward to the technological development of hot air non woven fabrics.

Spinning fine denier is an important trend in the development of nonwovens technology, because people pay more and more attention to the thinness and lightness of hygiene products. Using fine denier fibers can achieve better results, can reduce the surface density of non-woven fabrics, improve product uniformity, and reduce the cost of diaper production. At the same time, people have higher and higher requirements for the bulkiness and softness of diapers. Using high-crimp fibers to produce hot-air water-repellent non-woven fabrics is an effective way to improve the bulkiness of products. Through the corresponding improvement of material properties, it is possible to reduce the occurrence of fluff and improve the abrasion resistance of the fabric, which is the goal of equipment manufacturers and non-woven fabric producers to improve.

The compounding of materials can greatly improve the overall quality and effect of the material, and can improve the current deficiencies of hot air and water-repellent non-woven fabrics. Therefore, it can be compounded with other materials during the production process, which can combine the inherent characteristics of the material. , to make better use of the advantages of materials. The use of secondary processing is conducive to the perforation and three-dimensional shaping of the fabric, thereby reducing the contact area between the diaper product and the skin, reducing material fluff, and improving comfort.

The barrier property of materials is an important criterion for the production and design of diapers, because leakage prevention is the basic function of diapers, and improving the barrier properties of hot air water-repellent non-woven fabrics is a problem that raw material manufacturers need to pay attention to. In the process of production, manufacturers should adopt the method of quick mold change to realize different colors and embossing, reduce costs and improve the flexibility of production.

Hydrophobic air through non woven fabric plays an important value and role in improving the overall performance and quality of diapers. From the perspective of the technological development of hot air non-woven fabrics, relevant manufacturers should increase investment in equipment, processes and formulations, strengthen technical Innovation, using more reasonable and cost-effective materials for production.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China