Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-03

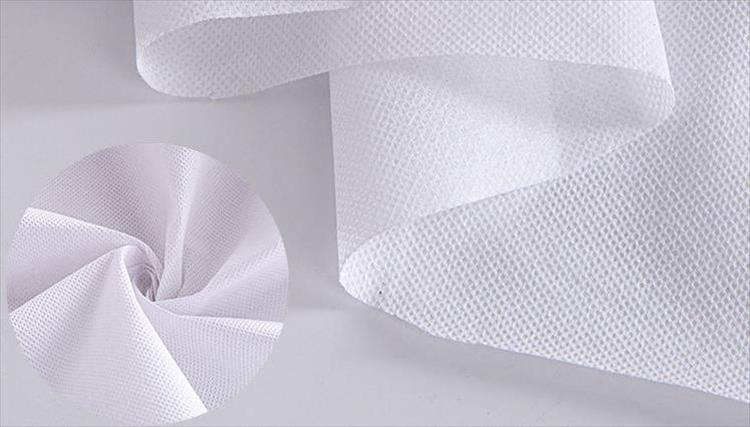

With the continuous development of non-woven fabric technology at home and abroad in recent decades, disposable sanitary non-woven fabrics have been upgraded, and new products have emerged one after another. The requirements of disposable products for materials are breathability, rapid moisture absorption, moisture permeability, anti-backflow and skin contact comfort. This article introduces the new raw materials of non-woven fabric for disposable hygiene, including non-woven fabrics of new surface layer and new absorbent core layer.

In the daily use of disposable hygiene products, the surface layer non-woven fabric is in close contact with the skin and only plays the role of diverting urine, and the liquid absorption is almost zero. Therefore, its skin-friendliness is improved and the reduction of The impact of disposable hygiene products on the quality of life of users is the biggest challenge in their design and development. Currently, the commonly used surface layer non-woven materials have been difficult to meet the diversified needs of consumers.

Silk fiber is a high-grade textile fiber raw material. The fiber is smooth, thin and soft, and has good skin adaptability. The friction stimulation coefficient with human skin is only 7.4%, and it has good safety and environmental protection. Therefore, silk fibers have good application potential in non-woven fabrics for disposable hygiene products, and can develop high-end diapers, sanitary napkins and pads with health care functions.

Screening new fiber raw materials for application in non-woven fabrics, and optimizing material structure and process technology is one of the direct methods to improve the performance of disposable hygiene products.

As the demand for disposable hygiene products increases year by year, the usage of fluff pulp fibers and SAP, the main raw materials of the absorbent core layer of disposable hygiene products, also increases simultaneously. However, this conflict with the rising price of fluff pulp raw materials, so that more and more people begin to pay attention to the development and research of new materials and new processing methods in the production of absorbent core layers.

Different from the current absorbent core of disposable hygiene products formed by mixing fluff pulp with SAP, the future absorbent core will strive to reduce the amount of fluff pulp, and even produce a core without fluff pulp, so that the core has higher liquid absorption capacity. In the market competition of disposable hygiene products, product cost determines its price competitive advantage to a large extent. Therefore, one of the current research trends is to reduce the cost of product manufacturing by processing raw materials.

The development of Super Absorbent Fiber (SAF) also provides a new research direction for the development of disposable hygiene products. SAF has a water absorption rate that is tens to hundreds of times higher than that of conventional synthetic fibers, and has many advantages that SAP cannot match. Advantages, such as: simple operation process, can be directly mixed with other fibers, and can be well combined with non-woven fabrics; fibers absorb water, expand and deform less, and are not easy to slide when entangled with other fibers; microporous structure, fast water absorption, etc. .

The birth and rapid development of disposable hygiene products have changed the lives of countless old and young women and children, and affected the progress of human civilization in the 20th century. Understanding the progress of raw materials of non-woven fabrics for disposable hygiene will help people better understand related industries.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China