Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-09

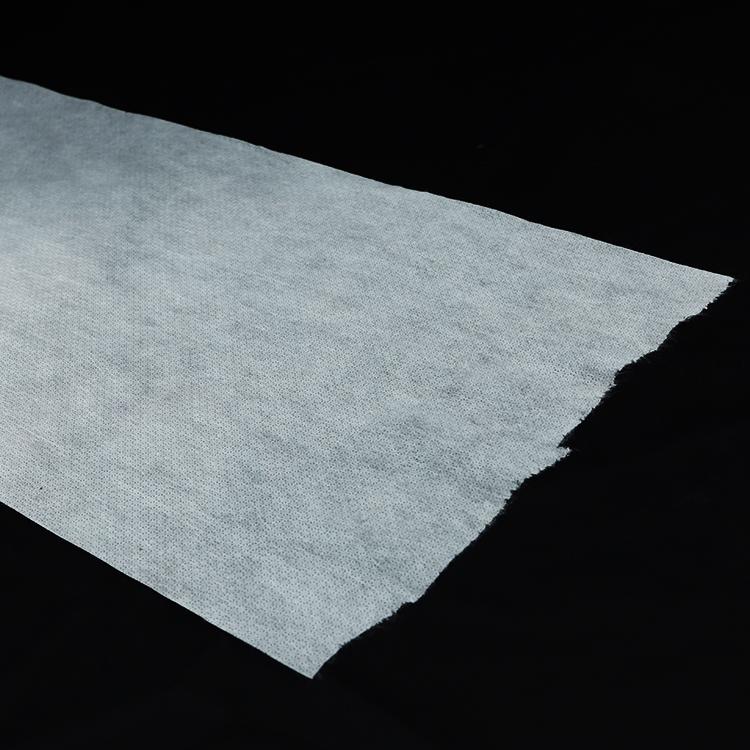

Spunbond and meltblown nonwovens have been widely used in consumer and industrial products. With the improvement of modern composite technology, SMS composite fabrics (spunbond/meltblown/spunbond) and SMMS, SMA or SASAM composite fabrics have come out one after another. This paper introduces the process of SMMS fabric.

Spunbond nonwovens are developed on the basis of chemical fiber melt spinning. The polymer melt extruded from the spinneret hole is cold-cut and drawn by cold-cut airflow and high-speed airflow to form The continuous filaments are then formed into a web on a coherent mesh curtain and consolidated to form a spunbond nonwoven. Melt-blown nonwovens use high-speed hot air to draw the thin stream of polymer melt extruded from the spinneret hole of the die, thereby forming ultra-fine fibers and condensing on the condensing screen or roller, and forming by self-adhesion. Non-woven. The application of meltblown technology to spunbond technology has made the spunbond nonwoven technology have a greater development due to the use of a special structure of the drafter.

Spunbond and meltblown equipment are on the same production line, that is, on the same product production line, and have 2 spunbond spinnerets and 2 meltblown die heads at the same time. The advantages of this production method are obvious. Compared with Off-line method and one-step and a half method, the multi-layer fiber web of this process only undergoes hot rolling once, and the product itself is very advantageous in terms of flexibility; at the same time, because it is formed in one step, there will be no width that often occurs in the previous two methods. Inaccurate width, roll length is not easy to control, etc. cause waste. At present, the use of PP in the global nonwoven disposable hygiene products market exceeds 80%. With the rapid development of spunbond/meltblown nonwoven technology, spunbond/meltblown nonwovens are widely used in product applications. It can be used in health care supplies, medical surgical supplies, industry, agriculture, etc.

Spunbond and meltblown nonwovens contribute significantly to the global nonwoven web trade. These extrusion processes have become the dominant force in various nonwovens markets and are considered by some to be the key to the next innovation in nonwovens technology. Understanding these two processes will help people to further understand SMMS fabric.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China