Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-08

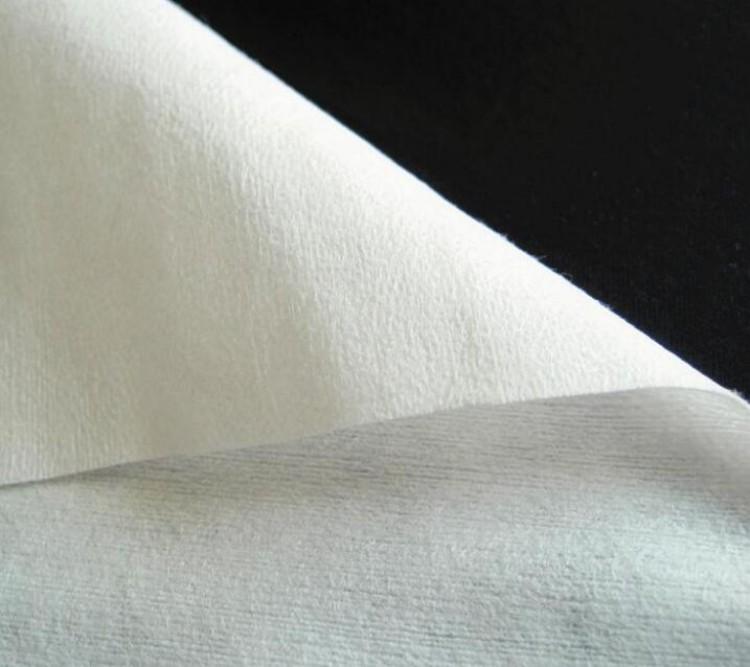

Spunlaced nonwoven products have the characteristics of soft hand feeling, good hygroscopicity, good air permeability, and no chemical adhesives. They are widely used in the fields of medical care, health care, and beauty products, such as protective clothing, masks, disposable gauze, Surface layer of sanitary napkins, wet wipes, etc. Such products have very strict hygienic requirements for spunlace nonwovens, so microbial contamination of spunlace nonwovens must be eliminated. There are six main factors affecting product microorganisms: personnel, machines, raw materials, methods, environment, and measurement. This paper analyzes the Plain Spunlace non woven fabric for wet wipes from the two influencing factors of personnel and machines and puts forward corresponding preventive measures.

Personnel is the biggest source of pollution, and it is also a difficult point in the production management of Plain Spunlace non woven fabric for wet wipes. Factors such as the operator's quality awareness, understanding of microbial control, and attitude towards work directly affect product quality. Reasons for microbial contamination caused by personnel: poor sense of responsibility, irregular disinfection, weak quality awareness, unskilled operation, non-compliance with operating procedures, etc. Preventive measures: Operators frequently take baths, change clothes, and cut hair frequently; enter the workshop to change work clothes and work shoes, wear masks and hats; disinfect hands with alcohol, wear gloves, disinfect soles, etc.; regularly conduct quality training to improve employees' sense of responsibility and Quality awareness; conduct regular operation and use training to improve the operating standards and operating level of employees.

Machines refer to production equipment and process components. Products are in contact with equipment during the process of fiber removal, feeding, web forming, reinforcement of Plain Spunlace non woven fabric for wet wipes, drying, cutting, and packaging. Influencing factors include: machine disinfection is not standardized, cleaning is not thorough, maintenance is not timely, etc.; the temperature of the dryer is too low, the moisture is not drained in time, the drying is not thorough, and the damp cloth surface will also lead to the growth of microorganisms; the surface of the pipeline is not smooth, Severe flower damage and flower accumulation; oil leakage of equipment, defects, and sick operations, etc. Preventive measures: In the production process, from raw material input to net laying, the whole process should be carried out in a sealed equipment and pipeline system. The pumps and pipelines of the production equipment used should be made of stainless steel; the surface of the machine should be cleaned and disinfected regularly; the dryer Set the appropriate temperature and timely dehumidify; the equipment is regularly inspected and maintained to prevent sick operations.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China