Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-15

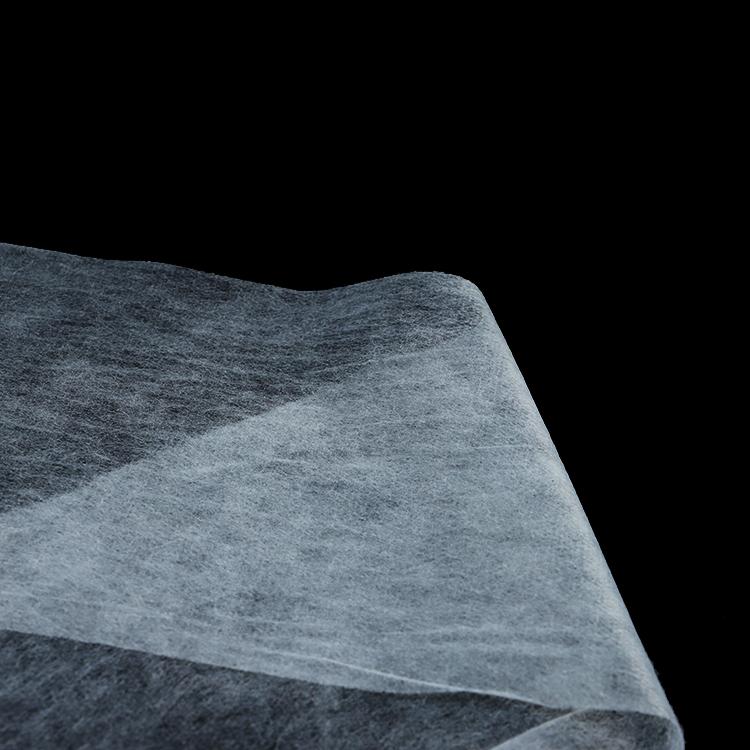

The spunbond method (Spunbond) is melt spinning to form a web, which is to heat and melt the polymer, and extrude the melt from the spinning hole into the air through the extruder. Stretching at a certain speed becomes thinner and longer (airflow or mechanical action), and at this stage, the polymer melt is refined and solidified at the same time, thereby forming fibers and then forming a network. Spunbond fabric is also called filament nonwoven fabric. Its key technologies are spinning, stretching, web laying and web forming. From this point of view, spunbond method is an integration of chemical, plastic, papermaking, chemical fiber and other industries. Comprehensive technology involving many disciplines. From the perspective of industry ownership, although spunbond fabric belongs to a branch of the textile industry, it has become a relatively independent and vigorous production industry; at the same time, since spunbond fabric is mainly made of polypropylene chips or polyester chips directly into the net Therefore, it is also closely related to the fields of petrochemical and emerging materials industries.

Compared with traditional nonwoven fabric processing technology, spunbond fabric has the advantages of advanced technology, short process flow, low cost, high labor productivity, large per capita output value, easy access to raw materials, excellent product performance and wide application; secondly, spunbond fabric has a large number of The use of polypropylene or polyester as raw materials has advantages in chip price, processing process, production cost, etc.; in addition, spunbonded nonwoven products have excellent mechanical properties, such as isotropy, tensile strength, elongation at break, tear Strength and other indicators are superior to dry, wet, and melt-blown nonwovens, so it can meet the needs of products for various purposes, greatly expanding the traditional application areas of nonwovens, and is a promising new technology.

Since 2000, the world's spunbond technology has been further improved, and has developed in the direction of fine denier, multi-component, multi-polymer spinnability, and process combination. As a differentiated fiber, two-component composite fiber conforms to the development trend of synthetic fibers and becomes the source and development direction of fibers for spunbond fabric production.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China