Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-04-13

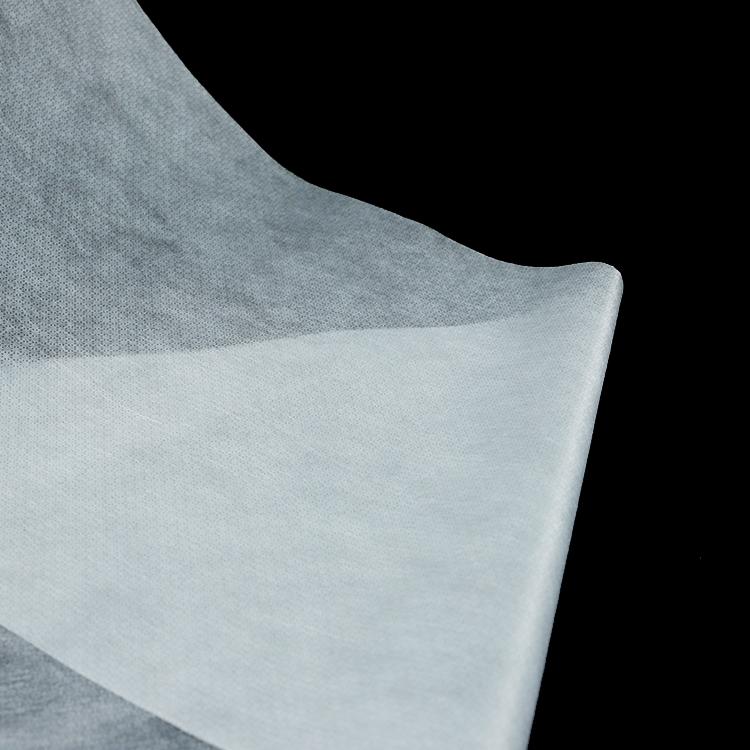

Water-repellent finishing is to change the hydrophilicity of the fiber surface to hydrophobic through the action of water-repellent finishing agent, so as to achieve the purpose of being breathable and not easily wetted by water. The water-repellent performance of waterproof fabric for diapers can be obtained by methods such as coating, functional finishing and compounding. According to the requirements of the product's water repellency, through the water repellent finishing agent and appropriate finishing technology, the finishing agent is coated on the surface of the material or bonded with the fiber macromolecules to endow the material with water repellency. In the process of producing waterproof fabric for diapers, the fibers can also be treated with water repellency by using technologies such as plasma or corona discharge, and then water-repellent fibers can be used to produce water-repellent nonwoven products.

Water-repellent finishing mainly uses low-surface tension finishing agents to make the surface tension of the nonwoven fabric much lower than that of water, so that the surface of the nonwoven fabric has a water-repellent effect, and the nonwoven fabric can continue to maintain good air permeability , sometimes called breathable waterproof finishing. The effect of water-repellent finishing is related to the critical surface tension of the material after finishing. The necessary condition to achieve water-repellent performance is to make the critical surface tension of the material smaller than the surface tension of the liquid (such as water, oil). Only when the contact angle of water on the surface of the material is >90° can it be both breathable and water repellent. When the droplet is in equilibrium on the solid surface, it is subjected to three forces at the junction of the three phases and satisfies the young (Young's) equation.

In the 1970s, botanist William Bartlot of the University of Bonn in Germany proposed the lotus leaf effect. The lotus leaf effect mainly refers to the characteristics of superhydrophobicity and self-cleaning on the surface of the lotus leaf. Because the lotus leaf has a hydrophobic surface, the rain falling on the leaf surface will form water droplets due to the effect of surface tension, and the contact angle between the water and the leaf surface will be >140°. As long as the leaf surface is slightly inclined, the water droplets will roll away from the leaf surface. noodle. Bartlot found under the microscope that the surface of the lotus leaf has a layer of hairs and some tiny waxy particles. Water on these nano-sized particles will not diffuse to other directions on the surface of the lotus leaf, but form small water droplets one by one. beads. From the water repellency principle of the lotus leaf effect, it can be seen that materials with high water repellency must meet two basic conditions: first, the surface of the material must have basic water repellency; at the same time, the surface with a certain roughness must reach the nanometer level . The lotus leaf effect is just the opposite of our previous understanding of plants' water repellency, which shows that people's previous view that the smoother the surface, the more water repellent is wrong. The lotus leaf effect plays a very good guiding role in the water-repellent finishing of materials.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China