Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-04-27

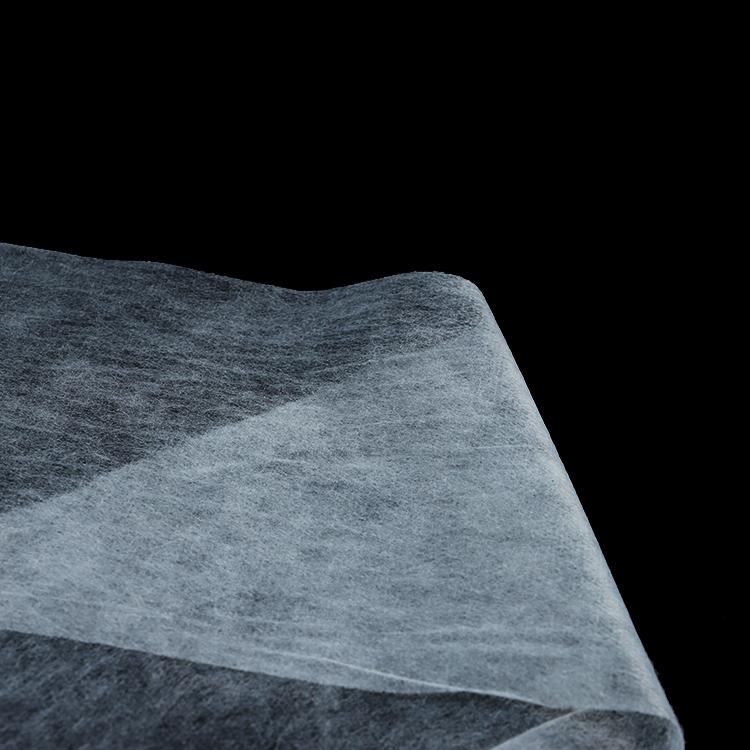

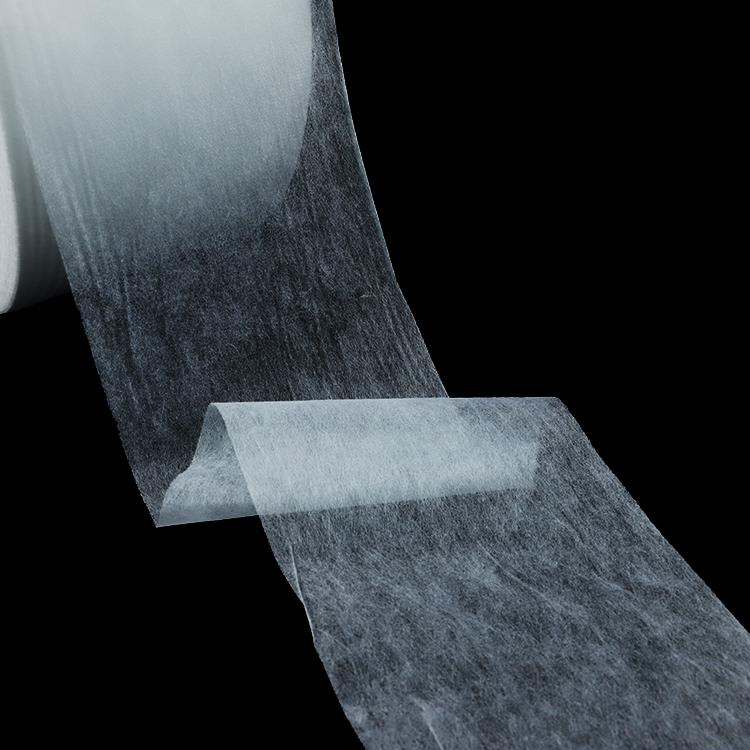

Non woven spun bonded fabric technology is a kind of nonwoven fabric production technology with rapid development and high technical content in recent years, and it is one of the main processing methods of nonwoven fabric at present. This method is a one-step cloth nonwoven technology, not only has unique characteristics in terms of process route and equipment structure, but also the processed products have their own characteristics. Polypropylene spunbond non-woven fabric is mainly a non-woven fabric formed by melting and spinning polypropylene slices through a screw extruder to form a web, and the fiber web is bonded and consolidated by hot rolling. When non-woven spun bonded fabric is used as disposable sanitary materials, especially when it is used as the surface material of baby diapers, hydrophilic finishing must be carried out to improve its hydrophilicity. There are many ways to improve the hydrophilicity of non-woven spun bonded fabric and improve the wettability of its fiber surface. This article introduces the modification in the spinning stage to obtain the hydrophilicity of the fiber.

It is a simple and effective method to add hydrophilic substances to polypropylene masterbatch to endow it with hydrophilic and hygroscopic properties. The added hydrophilic substances should have sufficiently low surface tension and strong hydrophilic groups, and have good thermal stability. Chen Qingkui and others blended polyethylene glycol octylphenyl ether, sodium dodecylbenzenesulfonate and octadecyl alcohol with polypropylene. Since the added surface activity is incompatible with the polypropylene matrix, it can spontaneously It migrates from the inside to the surface, endows the masterbatch with good hydrophilicity, reduces the viscosity of the polypropylene melt, improves fluidity and reduces the outlet expansion rate, which is beneficial to its melt processing.

Adding hydrophilic masterbatch in the non woven spun bonded fabric spinning process, the hydrophilic effect is long-lasting, and the production cost is low. It has a certain market share in the domestic spunbond production industry. However, due to the hydrophilic non woven fabric produced by this process The uniformity of the hydrophilic effect of spun bonded fabric is not good, and the indicators of hydrophilicity evaluation are not as good as those of post-finishing hydrophilic modification, so it is not widely used in the coating material of baby diapers, and can only be used in some low-end hygiene products. Material industry, such as pet pads, absorbent materials, etc.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China