Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-25

Unveiling the Benefits of Hydrophobic SMMS Non Woven Fabric in Diaper Manufacturing

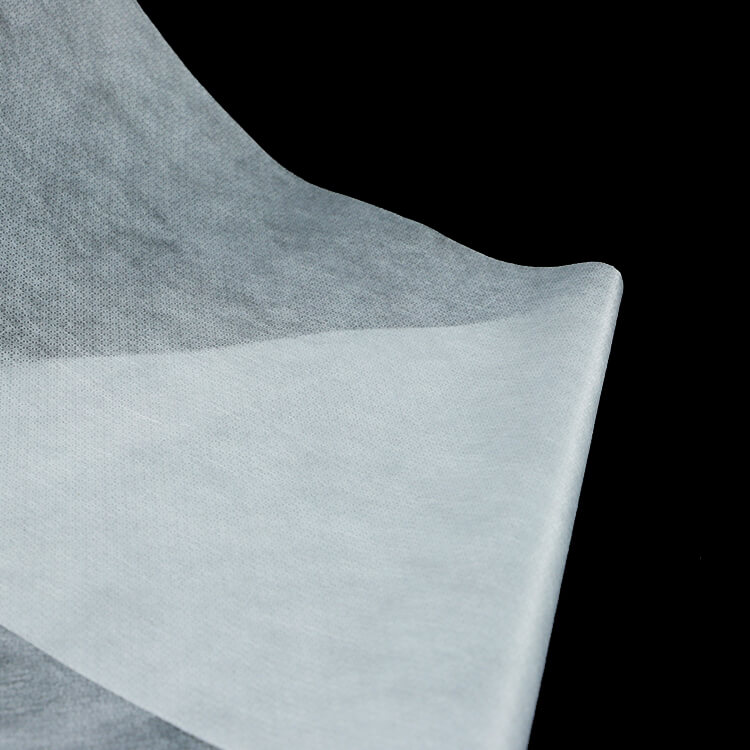

In the realm of diaper manufacturing, the choice of materials plays a crucial role in ensuring product quality and performance. One such material that has gained significant attention is hydrophobic SMMS (Spunbond-Meltblown-Meltblown-Spunbond) non-woven fabric. This innovative fabric offers several benefits that contribute to the overall effectiveness and comfort of diapers. In this article, we will explore the various advantages of using hydrophobic SMMS non-woven fabric in diaper manufacturing and highlight its positive impact on both manufacturers and end-users.

A key benefit of hydrophobic SMMS non-woven fabric in diaper manufacturing is its enhanced absorption capacity. Through a combination of spunbond and meltblown technologies, this fabric achieves an optimal balance between liquid permeability and retention. The hydrophobic nature of the fabric prevents liquid from passing through, ensuring that it stays within the absorbent core of the diaper. This feature significantly reduces the risk of leakage, providing a more reliable and comfortable experience for the wearer. Additionally, the fabric's ability to quickly distribute and lock away moisture helps to keep the surface dry, further enhancing comfort and reducing the likelihood of skin irritation.

Another advantage of hydrophobic SMMS non-woven fabric is its superior breathability. The unique structure of the fabric allows for efficient air circulation, preventing the build-up of heat and moisture inside the diaper. This enhanced breathability not only keeps the diaper area cooler but also helps to maintain optimal skin health by reducing the likelihood of diaper rash and other skin irritations. Furthermore, the fabric's soft texture provides a gentle and comfortable feel against the baby's skin, ensuring maximum comfort during prolonged use.

Hydrophobic SMMS non-woven fabric offers exceptional durability, making it an ideal choice for diaper manufacturing. The fabric's high tensile strength and resistance to tearing ensure that the diaper remains intact even under significant stress or movement. This durability translates into fewer product failures, reducing waste and improving overall cost efficiency. Additionally, the fabric's resistance to deformation and degradation over time ensures that the diaper maintains its performance and shape throughout its intended use, enhancing user satisfaction and brand reputation.

Hydrophobic SMMS non-woven fabric has revolutionized the diaper manufacturing industry by offering a range of benefits that improve both the functionality and comfort of diapers. Its enhanced absorption properties, leakage prevention capabilities, improved breathability, and durability make it an excellent choice for manufacturers seeking to produce high-quality diapers. By incorporating this innovative fabric, manufacturers can meet the demands of discerning consumers while also achieving cost efficiency and maintaining a positive brand image. Overall, hydrophobic SMMS non-woven fabric raises the bar for diaper performance and sets a new standard for excellence in the industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China