Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-30

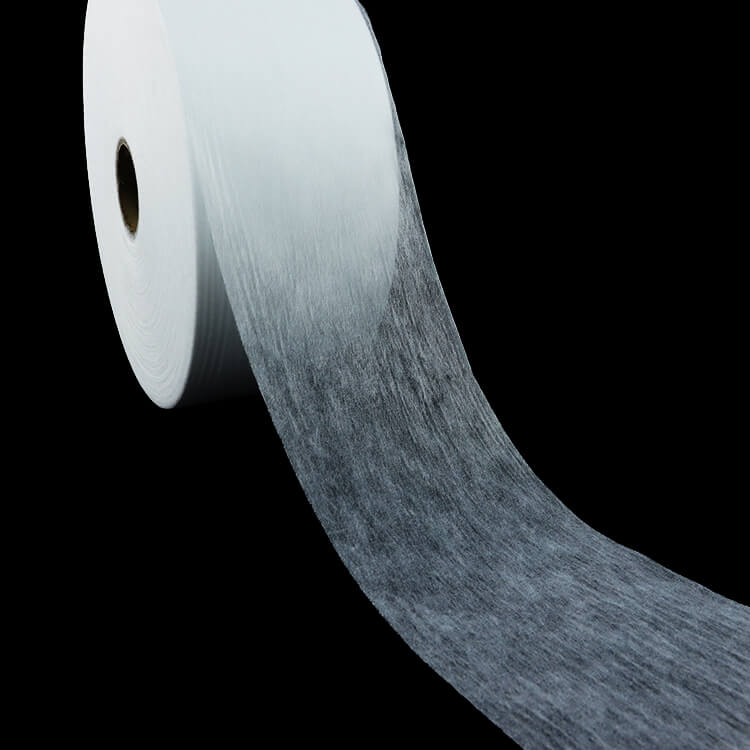

Laminated spunbond fabric is a crucial component in the production of diapers. It provides key properties such as breathability, liquid resistance, and softness, ensuring comfort and hygiene for infants. Understanding the essential knowledge on laminated spunbond fabric is vital for diaper manufacturers to produce high-quality products that meet the needs of parents and caregivers. This article will delve into the key aspects of laminated spunbond fabric for diaper production.

Laminated spunbond fabric for diapers consists of multiple layers that are bonded together through lamination. The primary layer is made of spunbond nonwoven fabric, which is composed of continuous filaments that are thermally bonded. This layer provides strength and durability to the fabric. Another crucial layer is the film, typically made of polyethylene or polypropylene. The film acts as a barrier against liquid penetration, preventing leakage. The bonding between the spunbond fabric and the film is achieved through adhesives or thermal processes, ensuring a secure and effective lamination.

Laminated spunbond fabric offers several key properties that are essential for diaper production. Firstly, it provides breathability, allowing air circulation to keep the baby's skin dry and comfortable. This is achieved through the porous structure of the spunbond fabric, which allows moisture vapor to escape while preventing liquid absorption. Secondly, the film layer provides excellent liquid resistance, preventing any leakage and keeping the diaper dry. Moreover, laminated spunbond fabric offers a soft and smooth texture, ensuring a gentle touch to the baby's delicate skin. Diapers made with this fabric provide reliable protection while maintaining comfort.

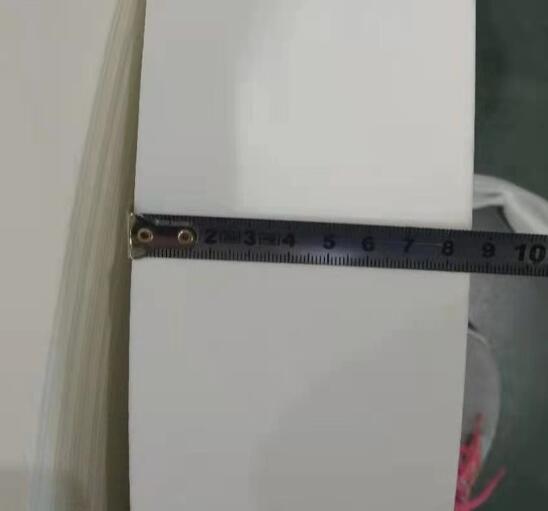

The manufacturing of laminated spunbond fabric involves several critical processes. Firstly, the spunbond nonwoven fabric is produced using a spinning process where the filaments are extruded, drawn, and then consolidated through thermal bonding. The film layer is separately produced through extrusion or casting methods. The subsequent lamination process involves bonding the spunbond fabric and the film together using either adhesives or thermal processes, such as hot melt lamination. Quality control during the production process is crucial to ensure consistent performance and adherence to specifications. Parameters such as basis weight, tensile strength, liquid resistance, and breathability are carefully monitored and tested to meet the desired standards.

In conclusion, a comprehensive understanding of laminated spunbond fabric for diaper production is crucial for manufacturers in the diaper industry. By knowing the composition, structure, properties, and manufacturing processes of this fabric, diaper manufacturers can produce high-quality products that offer comfort, protection, and hygiene for infants. As the demand for quality diapers continues to grow, having essential knowledge on laminated spunbond fabric will enable manufacturers to stay competitive and meet the needs of parents and caregivers worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China