Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Baby diaper, Adult diaper, Sanitary napkin

Minimum order quanity: 1000.00 kgs

Packing details: Transparent wrapping film with paper board

Acquisition distribution layer ADL non woven fabric roll features:

1. Accelerate the absorption of urine by the core

2. Make the diaper evenly thick after absorbing water

3. Reduce re-infiltration

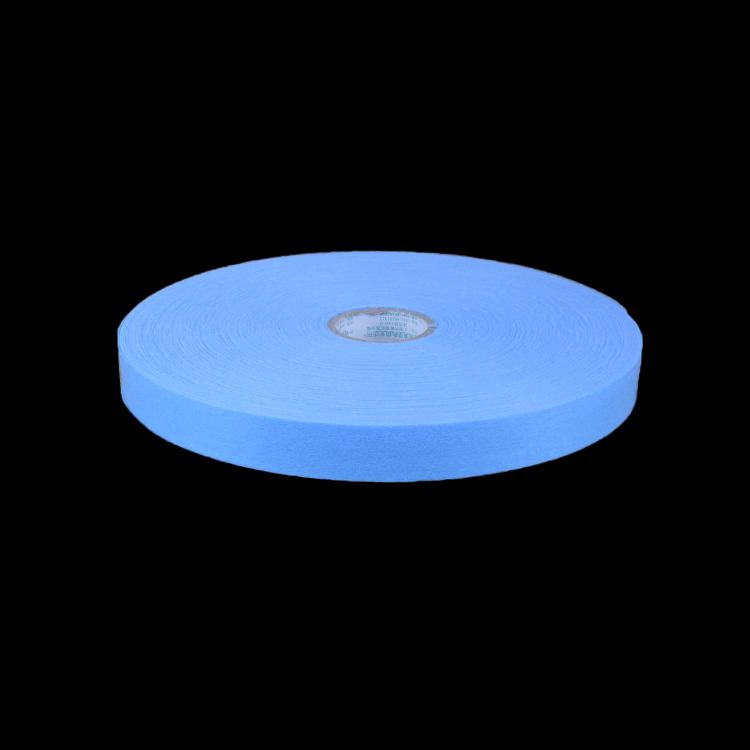

4. ADL non woven fabric is made by ES fiber, which can be white color, green color and blue color.

5.Application: baby diaper, sanitary napkin and adult diaper

6.Loading quantity:10.5 tons/40HQ, 4.5 tons/20GP.

|

All the test are lot production averages |

||||

|

Items |

Unit |

Requirement |

Result |

|

|

Color |

|

white |

white |

|

|

Core inside diameter |

mm |

76±1 |

76 |

|

|

Basic weight |

gsm |

50±2 |

49.6 |

|

|

Roll slit width |

mm |

65±2 |

65 |

|

|

Thickness |

μm |

0.8 |

0.81 |

|

|

Tensile strength |

MD |

N/5cm |

∕ |

70.2 |

|

CD |

∕ |

17.4 |

||

|

Breaking elongation |

MD |

% |

∕ |

42.6 |

|

CD |

∕ |

69.2 |

||

|

Others |

Wrinkles/ corrugation |

None |

||

|

Splices |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

|||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

|||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

|||

|

Material was suitable to use in hygiene product. |

||||

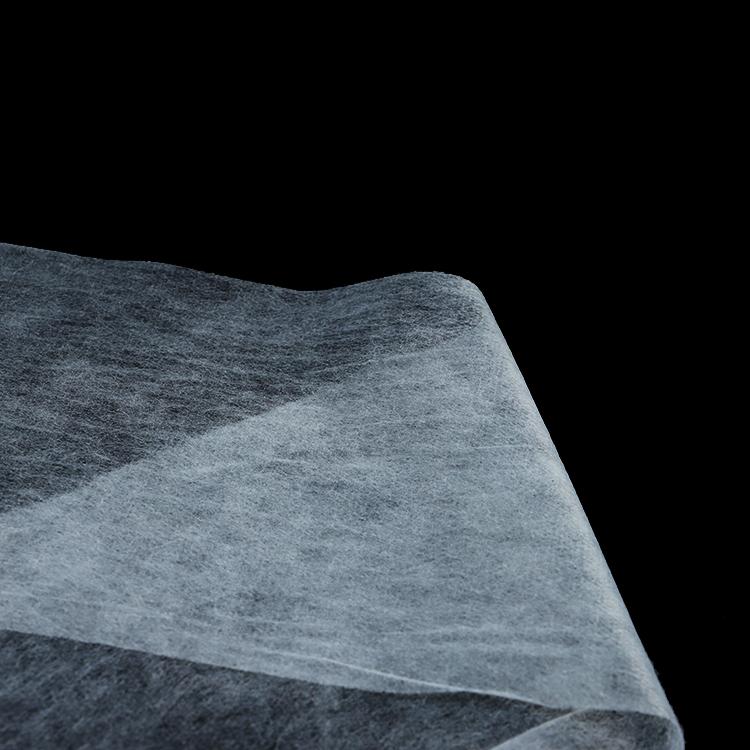

Air through non woven fabric is the ideal thermal bond fiber in ES hot air nonwoven fabric. When the carded web is thermally bonded by calendering or through-air, the low-melting c...

ADL Nonwoven Fabric is developed withairthrough bonded technology to be used for the production of baby diapers,sanitary napkins and incontinence diapers. ADL non woven features...

White color SS spunbond hydrophilic nonwoven wrapping non woven features: 1. Polypropylene is the key component ofthe sterile quality of spunbond non woven fabrics. 2.The mat...

Waistband non woven is one of the diaper making materials. It is used for the diaper waistband. There are three colors, white, green and blue. Basic weight is about 55gsm, and widt...

WEIHONGLAI export diaper non woven for customerin Bolivia. Polypropylene is the key component of thesterile quality of spunbond non woven fabrics. The material we offer has s...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China