Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

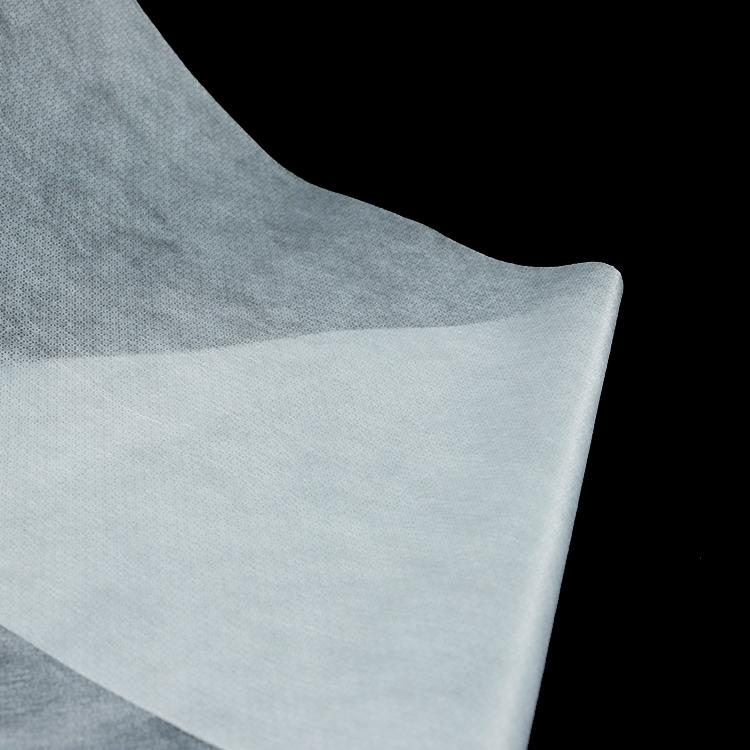

Hot air non woven is made of compound fibers which causes no stimulation or allergy to human body. They have achieved the national standard of hygiene pads production. They tend to have higher tensile strength in the MD and lower strength in the CD.

Weight: 18 – 50gsm

Width: 65mm-3600mm

Inner core diameter: 76mm

Outer diameter:580-780mm

Loading quantity:9-10tons/40HQ

|

Items |

Unit |

Requirement |

Result |

||

|

Min |

Max |

||||

|

Color |

/ |

white |

white |

||

|

Core inside diameter |

mm |

76±1 |

76 |

||

|

Basic weight |

gsm |

18±2 |

17.2 |

18.9 |

|

|

Width |

mm |

180±2 |

179 |

181 |

|

|

3D- Dimensional Thickness |

mm |

-0.2+0.3 |

0.43 |

0.49 |

|

|

Tensile strength |

MD |

N/5cm |

≥11 |

12.9 |

15.5 |

|

CD |

≥1.7 |

2.4 |

3.5 |

||

|

Breaking elongation |

MD |

% |

≥18 |

54 |

60 |

|

CD |

≥20 |

95 |

115 |

||

|

Fluid Penetrating Rate |

1st |

S |

≤2 |

1.03 |

1.25 |

|

2nd |

≤3 |

2.04 |

2.37 |

||

|

3rd |

≤4 |

2.6 |

3.01 |

||

|

Others |

Wrinkles/ corrugation |

None |

|||

|

Roll edge appearance |

Neat, Clean, No Obvious Defects |

||||

|

Contamination |

No Obvious Contamination; Free From Foreign Matter |

||||

|

Holes/Thin spots/Formation |

No Obvious Holes / Thin Spots / With Good Formation |

||||

Durable, disposable. Insulating,conducting. Softness, stiffness. fineness, expansion. Isotropic, anisotropic.Filterability, breathable and impermeable. Elasticity, stiffness. Ligh...

Weight: 18g/M2 to 60g/M2 as request Composition: 100% 6 Denier PE/PP Bicomponent fiber Color: white, blue,green Width: 25mm-2000mm or customized Application:baby diaper, adult d...

Spunlacenon woven fabric features: 1.Spunlace non woven fabric is made by viscose and polyester. 2.Spunlacenon woven fabric can be cross type or parallel type. 3.Spunlacenon wov...

We export 8*40HQ untreated fluff pulp to Pakistband customer. Untreated fluff pulp is shortage all whole the world. 40HQ can load about 25-26 tons. Untreated fluff pulp is used for...

In the highly competitive market for personal care products in Brazil, customers are always looking for ways to stand out and gain an edge over their competitors. One way to do thi...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China