Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-01

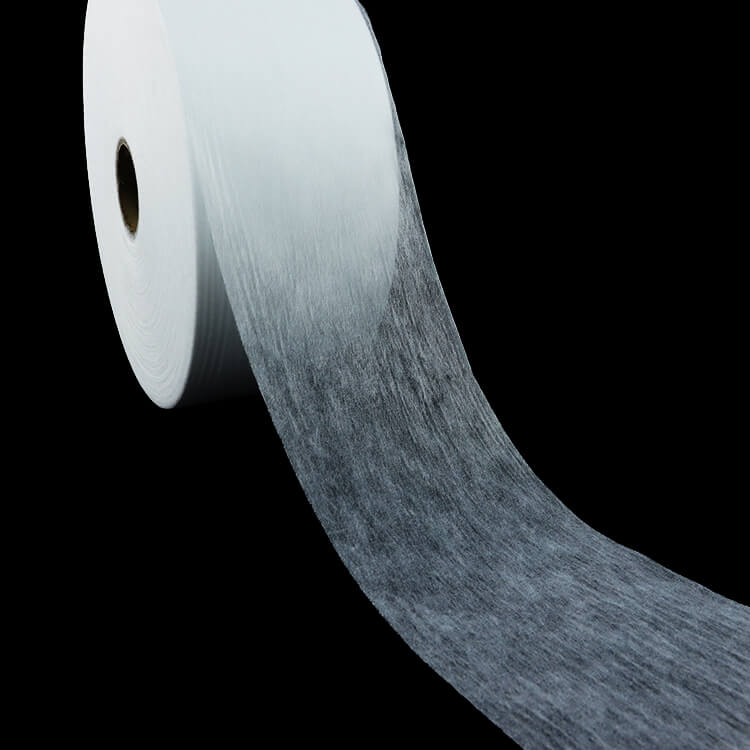

The use of spunbond non woven in diaper manufacturing has revolutionized the industry, offering numerous benefits and innovative applications. Spunbond non woven, a type of fabric made by bonding continuous filaments together, has become a popular choice for diaper manufacturers due to its exceptional properties and versatility. In this article, we will explore some of the key advantages and innovative applications of spunbond non woven in the diaper manufacturing process.

One of the primary advantages of using spunbond non woven in diaper manufacturing is its ability to enhance absorbency and provide effective leakage protection. The unique structure of spunbond non woven allows for excellent liquid absorption and distribution, ensuring that diapers can absorb and retain large amounts of urine or other fluids. This is crucial in keeping babies dry and comfortable, reducing the risk of skin irritation and diaper rash. Additionally, the strong tensile strength of spunbond non woven helps prevent leaks, providing reliable protection for extended periods.

Another significant application of spunbond non woven in diaper manufacturing is its contribution to breathability and comfort. Unlike traditional plastic-backed diapers, spunbond non woven allows air circulation, preventing heat and moisture build-up. This feature is essential in maintaining the optimal temperature and minimizing discomfort for babies. The soft and gentle texture of spunbond non woven also enhances overall comfort, making diapers more pleasant to wear for extended periods. Moreover, the lightweight nature of spunbond non woven ensures that diapers are not bulky, offering increased freedom of movement for active infants.

In recent years, there has been a growing emphasis on eco-friendliness and sustainability in various industries, including diaper manufacturing. Spunbond non woven has emerged as an eco-friendly alternative to traditional materials due to its sustainable production process and recyclability. The manufacturing of spunbond non woven involves fewer resources and energy compared to other materials, making it a more environmentally friendly choice. Furthermore, spunbond non woven can be easily recycled and reused, reducing waste and contributing to a more sustainable diaper manufacturing industry.

In conclusion, the innovative applications of spunbond non woven in diaper manufacturing have significantly improved the quality and functionality of diapers. Its enhanced absorbency and leakage protection provide reliable performance, ensuring babies stay dry and comfortable. The breathability and comfort offered by spunbond non woven enhance the overall user experience, while its eco-friendliness and recyclability contribute to a more sustainable future. With these advantages, it is evident that spunbond non woven has become an indispensable component in the manufacture of modern diapers, benefiting both manufacturers and consumers alike.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China