Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-03

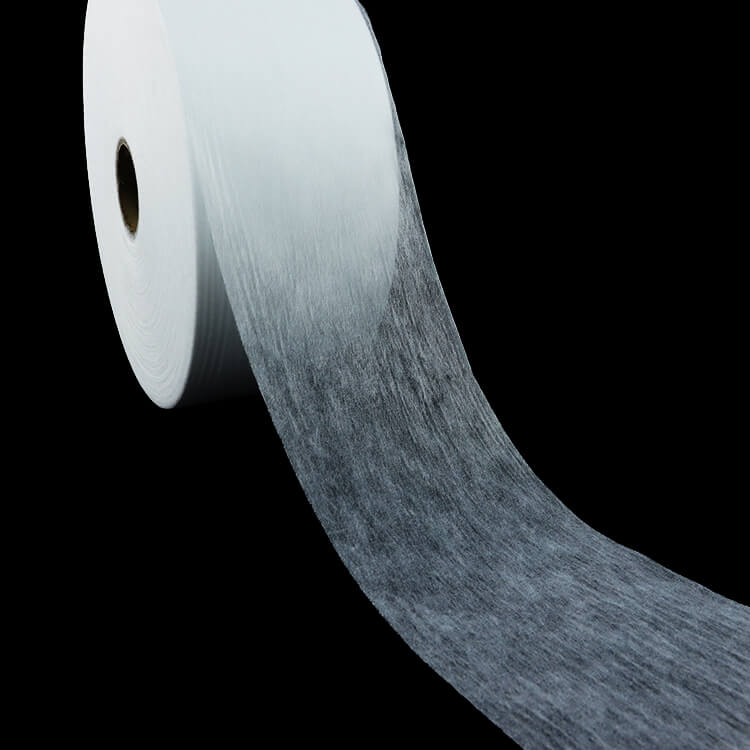

Spunbond Non Woven Revolutionizes Small Ear Diaper Production

In recent years, the demand for disposable diapers has skyrocketed due to their convenience and hygiene. To meet this increasing demand, manufacturers are constantly seeking innovative ways to improve production efficiency and reduce costs. One such revolution in the diaper manufacturing industry is the introduction of spunbond non-woven fabrics. This article will explore how this technology has transformed small ear diaper production.

The traditional process of manufacturing diapers requires multiple steps, including the application of adhesive tapes for the side tabs. With the advent of spunbond non-woven fabrics, this process has been simplified and streamlined. The fabric, made from continuous filament fibers bonded together thermally or mechanically, eliminates the need for adhesive tapes. This not only cuts down on material costs but also significantly reduces production time. Moreover, the lightweight and durable nature of spunbond non-woven fabrics contribute to better overall product performance.

In addition to reducing costs, spunbond non-woven fabrics also enhance production efficiency. The fabric is manufactured in a continuous process, allowing for high-speed automated production. This eliminates the need for manual handling and reduces the risk of errors. The consistent quality of the fabric ensures uniformity in the final product, meeting the stringent requirements set by customers. With increased production speed and reduced labor costs, manufacturers can produce larger quantities of small ear diapers in a shorter period, meeting the growing market demand.

Comfort is an essential factor when it comes to choosing diapers for babies. Spunbond non-woven fabrics offer enhanced comfort compared to traditional materials. The fabric is soft, breathable, and gentle on the skin, preventing rashes and irritation. The excellent moisture absorption properties of the fabric keep the baby's skin dry and comfortable, reducing the risk of diaper rash. Additionally, the non-woven structure allows for air circulation, minimizing the chances of bacterial growth and odor development.

Furthermore, spunbond non-woven fabrics contribute to the safety of small ear diapers. The fabric is free from harmful chemicals and allergens, making it safe for prolonged contact with delicate baby skin. The strength and tear resistance of the fabric ensure that the diapers do not leak or come apart during use, providing reliable protection for both the baby and parents.

The introduction of spunbond non-woven fabrics has revolutionized small ear diaper production. With improved efficiency, reduced costs, enhanced comfort, and increased safety, manufacturers can meet the growing demand for disposable diapers effectively. As this technology continues to advance, we can expect further innovations that will shape the future of the diaper manufacturing industry. Spunbond non-woven fabrics have undoubtedly brought significant benefits and improvements to small ear diaper production, making them the go-to choice for parents worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China