Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-08

Utilization of Non Woven Spun Bonded Fabric in Diaper Manufacturing

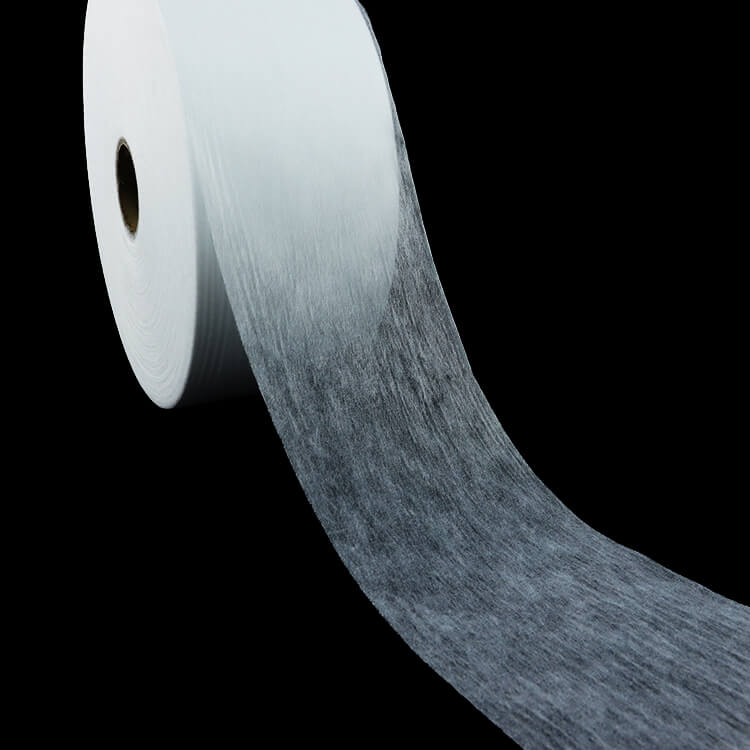

In recent years, the utilization of non woven spun bonded fabric in diaper manufacturing has gained increasing attention. Non woven fabric, made by bonding together fibers in a web-like structure, offers several advantages such as breathability, softness, and liquid absorption. These properties make it an ideal material for diaper production. This article aims to explore the various applications of non woven spun bonded fabric in diaper manufacturing and highlight its benefits.

One of the key advantages of using non woven spun bonded fabric in diaper manufacturing is enhanced comfort and breathability. The fabric allows air to pass through while still providing a barrier against moisture. This helps to reduce the risk of diaper rash and promote overall skin health. Additionally, the softness of non woven fabric contributes to the baby's comfort, ensuring a pleasant experience for the wearer.

Moreover, the breathability of non woven spun bonded fabric helps to regulate temperature and prevent overheating. This is particularly important in warm climates or during physical activities. By allowing excess heat and moisture to escape, the fabric keeps the diaper area dry and reduces the chances of discomfort or irritation.

Another significant advantage of utilizing non woven spun bonded fabric in diaper manufacturing is its superior liquid absorption and leakage prevention capabilities. The structure of the fabric enables it to quickly absorb and distribute liquid, keeping the surface dry and minimizing contact between the liquid and the baby's skin.

The high absorption capacity of non woven fabric ensures that the diaper remains comfortable for an extended period. It reduces the need for frequent changes and provides peace of mind to parents, knowing that their baby will stay dry and protected. Additionally, the fabric's ability to prevent leakage helps to maintain cleanliness and prevents accidents from soiling clothes or bedding.

Non woven spun bonded fabric also offers environmental friendliness and cost-effectiveness, which are important considerations in diaper manufacturing. Unlike traditional woven fabrics, non woven fabric does not require spinning, weaving, or knitting, reducing energy consumption and material waste during production.

Furthermore, non woven fabric is often made from recycled materials or can be easily recycled after use. This contributes to the reduction of waste in landfills and helps to promote sustainability. Additionally, the cost-effectiveness of non woven fabric makes it an attractive choice for manufacturers, allowing them to produce high-quality diapers at a reasonable cost.

The utilization of non woven spun bonded fabric in diaper manufacturing offers numerous benefits, including enhanced comfort and breathability, improved liquid absorption and leakage prevention, as well as environmental friendliness and cost-effectiveness. As the demand for comfortable and high-performance diapers continues to grow, non woven fabric proves to be a valuable material in meeting these requirements. With its unique properties, non woven fabric plays a crucial role in ensuring the well-being of babies and providing convenience to parents.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China