Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

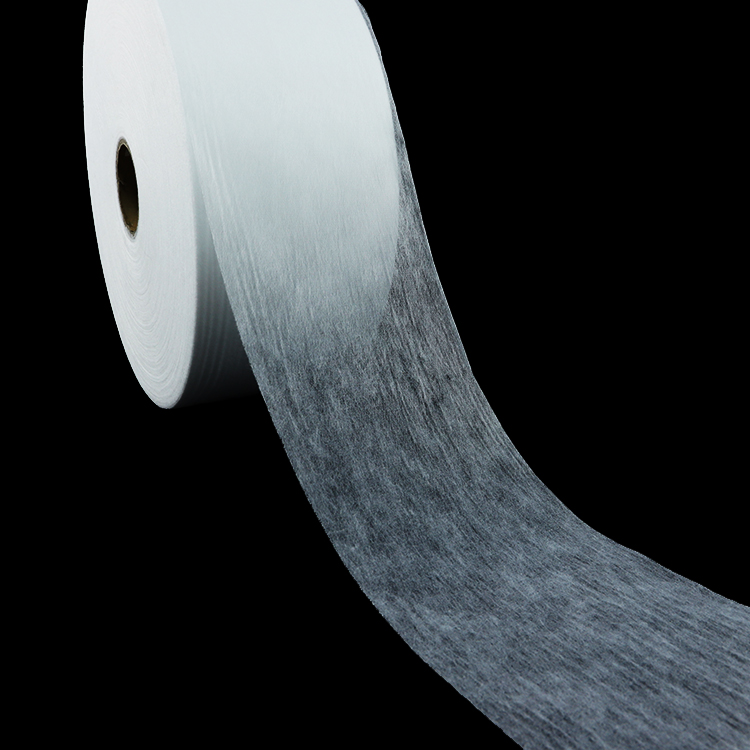

Enhancing Diaper Absorbency with Thermal Bond Nonwoven Fabric

Diapers are an essential product for infants and toddlers, providing comfort and protection against leaks. One crucial factor in the effectiveness of diapers is their absorbency. To enhance diaper performance, manufacturers have been exploring various materials and technologies. Among these, thermal bond nonwoven fabric has emerged as a promising solution. This article aims to explore the benefits and applications of thermal bond nonwoven fabric in enhancing diaper absorbency.

Thermal bond nonwoven fabric is a type of material created through a thermal bonding process. It involves the application of heat and pressure to melt and fuse synthetic fibers together. This results in a fabric that exhibits several beneficial properties for enhancing diaper absorbency:

1. Enhanced Liquid Retention: The unique structure of thermal bond nonwoven fabric allows it to retain a significant amount of liquid without leakage. The fused fibers create a barrier that prevents liquid from seeping through the fabric, keeping the diaper's surface dry and comfortable for the baby.

2. Rapid Absorption Rate: The thermal bond nonwoven fabric promotes a fast absorption rate due to its porous structure. The interconnected fibers create channels for the liquid to travel, allowing quick penetration and distribution throughout the fabric. This feature helps to minimize the risk of leakage and keeps the baby's skin dry and irritation-free.

3. Soft and Comfortable: Thermal bond nonwoven fabric is known for its soft and gentle texture. It provides a comfortable experience for babies, reducing the chances of diaper rash and skin irritation. The fabric's breathability also allows better air circulation, maintaining a healthier and drier environment for the baby's delicate skin.

The benefits of thermal bond nonwoven fabric make it an ideal material for various components in diaper manufacturing:

1. Top Sheet: The top sheet is the layer that comes in direct contact with the baby's skin. By using thermal bond nonwoven fabric as the top sheet, manufacturers can ensure excellent liquid retention, rapid absorption, and enhanced comfort for the baby.

2. Acquisition/Distribution Layer: This layer is responsible for quickly distributing the liquid throughout the diaper to prevent pooling and potential leakage. Thermal bond nonwoven fabric's fast absorption rate and efficient liquid distribution make it an effective choice for this critical component.

3. Core Wrap: The core wrap surrounds the absorbent core of the diaper, providing protection and preventing leakage. Thermal bond nonwoven fabric's liquid barrier properties make it an ideal candidate for this application, ensuring maximum containment and security.

In conclusion, thermal bond nonwoven fabric offers significant advantages in enhancing diaper absorbency. Its ability to retain liquid, promote rapid absorption, and provide a soft and comfortable experience makes it a valuable material for diaper manufacturing. As the demand for higher performance diapers continues to grow, the utilization of thermal bond nonwoven fabric is likely to increase. Manufacturers should consider incorporating this innovative material into their production processes to meet the evolving needs of parents and provide optimal care for babies.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China