Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-31

Nonwoven spunlace fabric plays a crucial role in the production of diapers. Its unique properties make it an essential material for providing comfort and absorbency. In this article, we will delve into the essential insights regarding nonwoven spunlace fabric for diaper production.

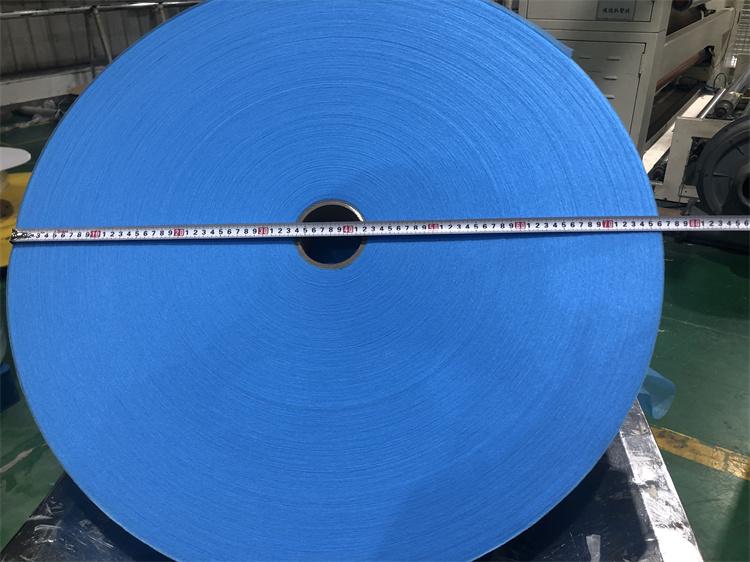

Nonwoven spunlace fabric is a type of nonwoven material produced by entangling fibers together through high-pressure water jets. This process creates a fabric with excellent strength, softness, and breathability. The fibers used in nonwoven spunlace fabric can be natural or synthetic, depending on the desired characteristics of the final product.

Nonwoven spunlace fabric is widely used in the diaper industry due to its superior absorbent capacity, liquid distribution capability, and skin-friendliness. It provides a comfortable and dry experience for babies and helps prevent rashes and irritation.

Enhanced Absorbency: Nonwoven spunlace fabric has a three-dimensional structure that allows it to hold a significant amount of liquid. It quickly absorbs and distributes urine, keeping the baby's skin dry and preventing leakage.

Softness and Comfort: The entangled fibers in nonwoven spunlace fabric create a smooth and gentle texture, making it ideal for delicate baby skin. The fabric provides a cushioning effect and minimizes friction, reducing the risk of diaper rash and discomfort.

Breathability: Nonwoven spunlace fabric has excellent air permeability, allowing moisture and heat to escape. This breathability helps maintain a healthy environment for the baby's skin and reduces the chances of skin irritation and bacterial growth.

The production process of nonwoven spunlace fabric involves several key steps. First, the fibers are opened and blended to create a homogeneous mixture. Next, the mixture is laid onto a moving belt or screen, and high-pressure water jets entangle the fibers together. Afterward, the fabric undergoes various treatments, such as drying, printing, and finishing, to enhance its performance and aesthetics.

To ensure the quality of nonwoven spunlace fabric used in diaper production, stringent quality control measures are implemented. This includes testing the fabric for tensile strength, absorbency, liquid distribution, and resistance to pilling. Additionally, proper handling and storage conditions are maintained to prevent any contamination or damage to the fabric.

In conclusion, nonwoven spunlace fabric is an indispensable material in the production of diapers. Its unique properties, such as enhanced absorbency, softness, and breathability, contribute to the comfort and well-being of babies. Understanding the insights into nonwoven spunlace fabric allows manufacturers to produce high-quality diapers that meet the needs of both babies and parents.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China