Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-09-14

Diapers are an essential part of modern parenting, providing convenience and hygiene for both babies and caregivers. As the demand for diapers continues to rise, there is a need for innovative materials that enhance their functionality and comfort. Nonwoven spunlace fabric has emerged as a promising option for diaper materials, offering numerous benefits in terms of softness, absorbency, and sustainability. In this article, we will explore the advantages of harnessing nonwoven spunlace fabric for diaper manufacturing.

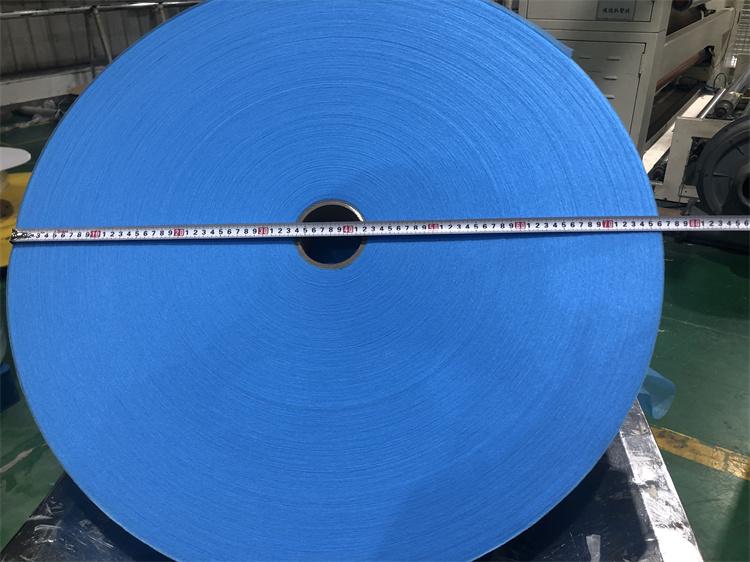

One of the key advantages of nonwoven spunlace fabric is its exceptional softness, making it ideal for baby diapers. The fabric is made by entangling fibers using high-pressure water jets, resulting in a dense yet delicate structure. This unique construction gives spunlace fabric a remarkably smooth and gentle feel, minimizing the risk of irritation or rashes on the baby's sensitive skin. Compared to other materials like woven fabrics or airlaid pulp, spunlace fabric offers superior comfort for prolonged wear.

In addition to its softness, spunlace fabric provides excellent breathability, allowing air circulation and preventing the build-up of heat and moisture. This enhances the overall comfort of the diaper, reducing the chances of discomfort or skin conditions caused by excessive dampness. The breathability of spunlace fabric also helps to regulate temperature, keeping the baby's skin cool and dry even during hot weather or physical activities.

Another significant benefit of nonwoven spunlace fabric in diaper manufacturing is its exceptional absorbency. The fabric's entangled structure creates numerous small channels and voids that can efficiently capture and retain liquid. This allows for rapid absorption and dispersion of urine, keeping the baby's skin dry and preventing leakage.

Compared to traditional materials like fluff pulp, spunlace fabric offers higher absorption capacity and faster wicking properties. This is particularly important for baby diapers, as it reduces the risk of diaper rash or discomfort caused by prolonged contact with wetness. The superior absorbency of spunlace fabric also contributes to fewer diaper changes, ensuring convenience for both caregivers and babies.

As the importance of environmental sustainability becomes increasingly evident, choosing eco-friendly materials for diaper production is crucial. Nonwoven spunlace fabric offers several advantages in this regard, making it a sustainable choice for diaper materials.

Firstly, spunlace fabric can be manufactured using a range of natural and synthetic fibers. This versatility allows for the utilization of renewable resources like bamboo, cotton, and viscose. By reducing reliance on non-renewable resources, spunlace fabric helps to minimize the environmental impact of diaper manufacturing.

In addition, spunlace fabric is highly biodegradable, meaning it can naturally decompose over time. This reduces the environmental burden associated with the disposal of used diapers, especially when compared to materials like plastic films or superabsorbent polymers. By choosing spunlace fabric for diapers, manufacturers contribute to a more sustainable future.

In conclusion, nonwoven spunlace fabric offers significant benefits for diaper manufacturing. Its superior softness and comfort, enhanced absorbency, and sustainability make it an excellent choice for both babies and the environment. By harnessing the advantages of spunlace fabric, diaper manufacturers can create products that prioritize the well-being of babies while minimizing their ecological footprint.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China