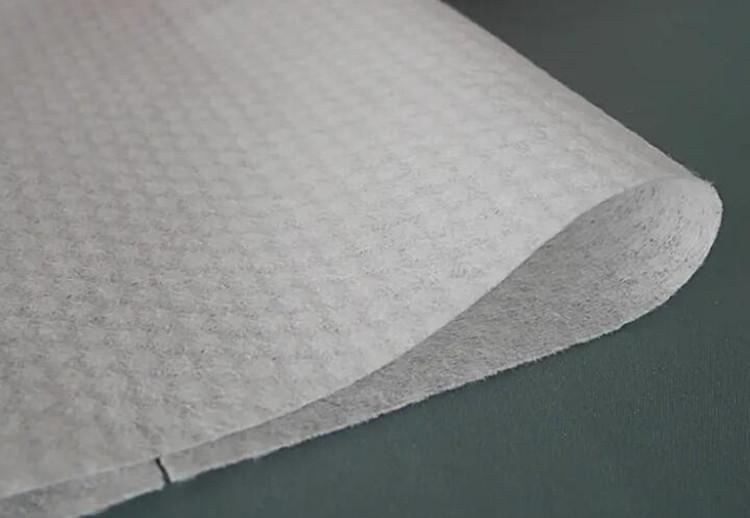

1. Color spunlace non woven, producing spunlace non woven of various colors, can be customized according to color samples. The dyeing process is: online dyeing, dyeing through the process of color paste, high temperature drying for color fixing, sizing and hardening, hydrophilic, water repellent, flame retardant and other special treatments. High temperature and high pressure immersion dyeing needs to be soaked in the dyeing tank for more than 8 hours, and the dyes will enter the entire structural layer of the fiber. The dyed cloth has strong color fastness, bright color and glossy surface.

2. The water repellent spunlace non woven is sprayed or soaked with water repellent agent on the cloth, forming a film on the surface that is invisible to the naked eye, and the molecular structure is smaller than that of water, achieving the purpose of waterproofing.

3. There are two flame retardant methods for flame retardant spunlace non woven. One: adding flame retardants when making fabrics. This type of treatment is used more, which not only achieves the purpose of flame retardant, but also reduces production costs. It can meet various flame retardant standards such as British Standard or American Standard. Two: use flame retardant fibers to achieve the purpose of flame retardant by adding flame retardant fibers, adding different proportions of flame retardant fibers, but this kind of production cost is high, and this method is rarely used.

4. The hydrophilic spunlace non woven can absorb water by adding a hydrophilic agent. It can absorb water without adding viscose fiber, which can greatly reduce the production cost.

5. The sizing of spunlace non woven is divided into thin pulp, thick pulp and extra hard pulp, which are used to change the hardness and stiffness of the cloth to suit different purposes. And can be treated with hydrophilic, water repellent, dyeing, etc

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366 Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China