Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-14

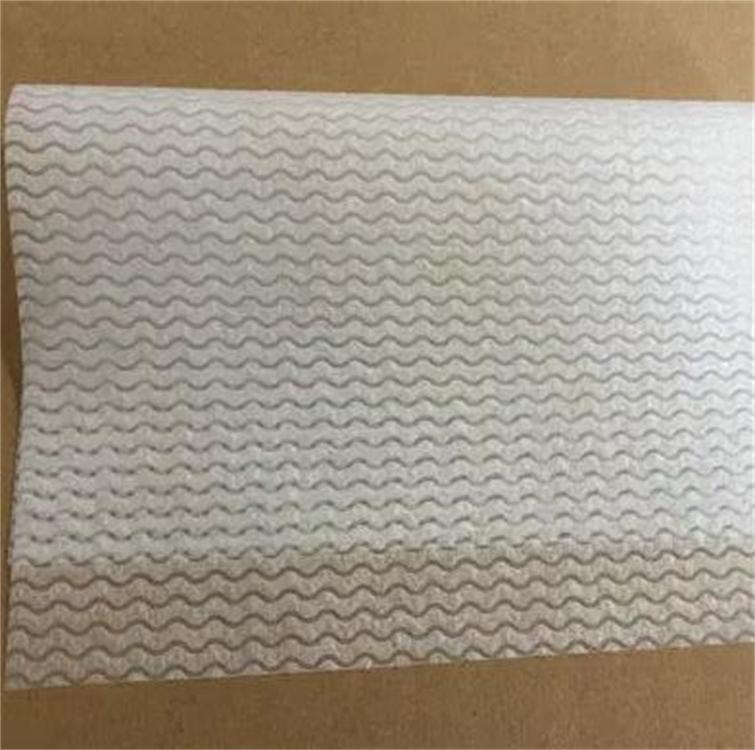

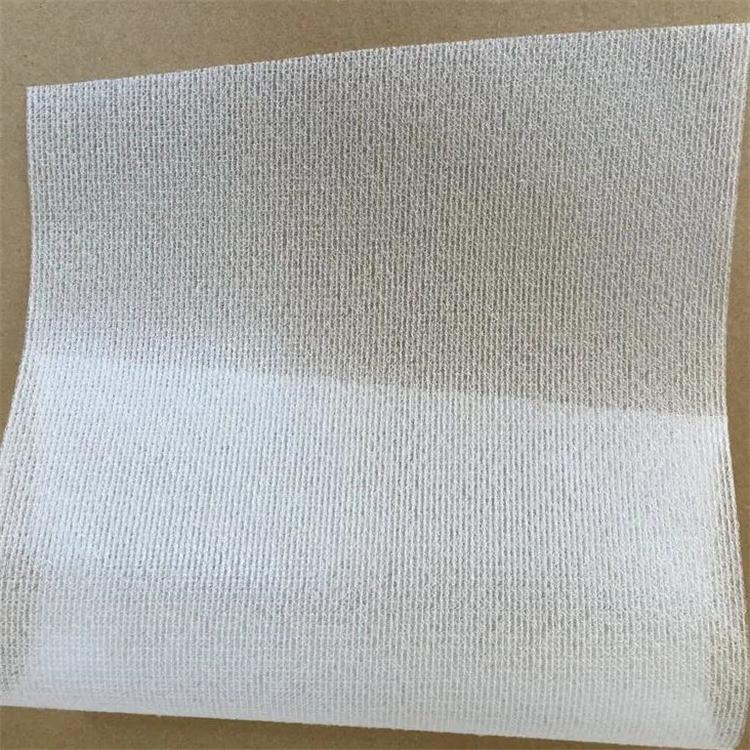

At present, non woven frontal tape are widely used in the field of hygiene products. This paper puts forward the countermeasures for the common problems of the Velcro machine in the actual production process.

The position of the non woven frontal tape is offset.The main reason is the incorrect position of the positioning ring of the storage shaft and the incorrect position of the material on the machine.

solutions:

A. Correctly use the positioning ring of the storage shaft. The distance from the machine board to the center of the material is 300mm.

B. When the material is installed, the core must be close to the inner positioning ring, and then the outer ring should be clamped to the outer core to fix it.

C. Use the top of the storage shaft and manually adjust the ring to adjust the left and right unwinding positions of the material.

Because the material is too loose during the winding process, the material is in a loose state when it is unrolled, so the material is wrinkled due to the uneven feeding of the material when it passes through the unwinding main shaft.

solutions:

A. Tighten the inner and outer ring positioning rings of the storage shaft when the material is put on the machine.

B. Adjust the unwinding adjustment ring to moderately increase the friction when the storage shaft rotates, so that the material can reach a certain degree of tension after unwinding.

That is, drop shaped yellow glue appears.

main reason:

A. The temperature of the glue gun is too high; 2. The squeegee angle of the glue gun is wrong; 3. There is a foreign body on the gun lip; 4. The material unwinding is unstable.

solutions:

(1). From the operation interface of the melter, set the temperature of the front waist sticker gun to about 125℃-135℃.

(2). Adjust the gluing angle of the scraping gun. Based on the material, the gun body is installed perpendicular to the material, or the gun body can be inclined about 10 degrees in the opposite direction of the material feeding.

(3). Stop the operation when there is foreign matter on the gun lip. Use the air gun to align the gun lip from the inside to the outside and use about 0.1mp of air pressure to clean the glue or debris on the gun lip. (Pay attention to using paraffin to clean the gun lip and gun body during daily maintenance)

(4). Detect whether the material is in close contact with the unwinding drive shaft, and increase the friction between the material, the unwinding shaft and the adsorption belt to achieve the synchronous state of material unwinding. Increasing the friction between the material and the unwinding shaft can change the contact area between the material and the unwinding shaft, and increasing the friction between the material and the adsorption belt can directly adjust the negative pressure of the adsorption tank to increase the adsorption force.

A. Discount for missing pieces after the front waist is cut and cut

main reason:The "white mouth" phenomenon of the slitting blade is caused by mechanical fatigue, which directly leads to continuous material cutting or incomplete slitting; 2. The slitting transfer suction is too small.

solutions:

(1). Use sandpaper to manually polish the knife edge to remove the burrs on the knife edge. 2. Moderately increase the cutting pressure. 3. Detect the position of the air distribution plate, and check whether the inside of the air distribution plate and the suction duct are blocked, causing the transfer suction to be too small.

(2) not sticky

Main reasons: 1. Insufficient amount of glue; 2. Insufficient transfer pressure.

solutions:

A. Check whether the pump speed of the melter is normal, check whether the glue output of the glue gun is normal, and check whether there is foreign matter at the lip of the gun.

B. Adjust whether the position of the pressure-assisting mandrel is appropriate after the front waist is pasted and cut, and increase the pressure of the pressure-assisting shaft after it is pasted.

main reason:

A. The sticking phase is inaccurate; 2. The unwinding and conveying of the bottom film is unstable.

solutions:

B. Adjust the phase and adjust the sticking position to the standard position of the product. If there is still a position offset phenomenon in the adjustment phase, check whether the rear transmission differential box, differential motor, synchronous wheel and synchronous belt of the rear and front waist sticking mechanism can work normally.

C. If the unwinding and conveying of the bottom film is unstable, you can check whether the unwinding system and the tension mechanism of the bottom film are working normally. If the unwinding system is still unstable in the normal state, the friction between the bottom film and the bottom film material conveying drive shaft can be increased to ensure the unwinding stability of the bottom film material.

Starting from the common problems of non woven frontal tape, understanding the corresponding countermeasures is conducive to better production of Velcro and serving people's lives.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China