Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-07

A normal sanitary pad must have a majority of fluff pulp in its absorbent body. Anyone who says that material sanitary pads do not have fluff pulp in them is not a professional in the field, but in fact the fluff pulp in sanitary pads is broken up on site during production. It is a roll of very stiff fibres, one for hygiene and one for ease of transport. The main reason for using fluff pulp is that this fluffy fibre is the fastest and most effective in absorbing liquids, because it has a "capillary phenomenon", but of course you may ask if the water is not squeezed out when you squeeze it gently. The absorbent resin absorbs water relatively quickly, but once absorbed the water never runs out. This fluff pulp + absorbent resin absorbent body is the most technically effective combination at present, not only for sanitary napkins, but also for nappies.

The properties of fluff pulp can be summarised in three parts, namely the general properties of fluff pulp, the properties of the fluff pulp board and the properties of the pile. the general properties of fluff pulp include whiteness, organic solvent extraction, fibre length and its distribution; the properties of the fluff pulp board include weight, tightness, breakage resistance and moisture; the properties of the pile include specific volume, wicking time and rate of wicking, moisture absorption. So sanitary napkins can't do without it! Let's start by understanding what fluff pulp is?

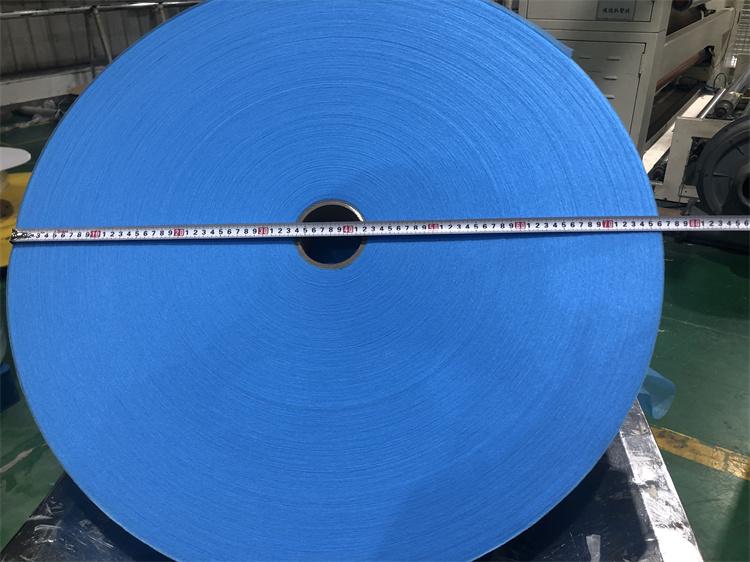

fluff pulp is a pulp used as an absorbent medium in the production of various hygiene products (e.g. sanitary napkins, baby nappies, hospital mattresses, etc.). Compared to normal pulp sheets, fluff pulp sheets have longer fibres and the fibres themselves are stronger, so that when producing fluff pulp products such as sanitary towels they can be easily dissociated into single fibres on the pile machine and generate less dust when processing the pile. The general requirements for fluff pulp products are good water absorption and rapid diffusion; high whiteness of fluff pulp fibres, soft fibres, a certain degree of elasticity and good core pad integrity, and compliance with the required hygiene indicators.

In the paper industry, fluff pulp first originated in Europe in the 1950s and was mainly used in the household paper sector. fluff pulp is widely used in the household paper sector because, compared to other common pulp, fluff pulp has long fibres, good strength, high density, a good fibrillation rate, a certain degree of elasticity and a good core pad integrity. This is why fluff pulp is used as an absorbent medium in a variety of hygiene products including dry tissue, premium napkins, facial tissues, square tissues and as pads for women's sanitary napkins, baby nappies, medical sanitary napkins, seamless medical cloth garments, surgical pads and other pads. For those sanitary napkins that claim to have no fluff pulp, the absorbent body is made of dust-free paper, which is also made of fluff pulp and is mainly used for ultra-thin sanitary napkins. So there is no such thing as a sanitary napkin with "fluff pulp", because fluff pulp itself is not harmful in any way. Coniferous wood is the best material sanitary pads for the production of fluff pulp, but our forest resources, especially coniferous wood, are scarce, so the development of new raw materials for the production of fluff pulp is of great practical importance to our country. It is important to note that when selecting raw materials, one should fully understand the required properties and processing performance of fluff pulp and analyse the chemical composition, cellular composition and superstructure of the raw material to determine its feasibility for the production of fluff pulp. GP is the largest commercial pulp producer in North America, with a capacity of nearly 2.3 million tonnes per year of fluff pulp, Southern Bleached Conifer Pulp and Southern Bleached Broadleaf Pulp, and GP is also the world's largest producer of fluff pulp.

Poor quality fluff pulp is often made from secondary recycled paper towels, sanitary napkins, offcuts and even rubbish, which are bleached with fluorescent agents to whiten the pulp and make it look white. Over ninety percent of sanitary napkins on the market contain fluorescent agents. According to medical clinical trials, fluorescent substances can cause cellular mutagenicity and may be potentially carcinogenic if there is excessive exposure to fluorescent agents. More importantly, unlike ordinary chemical ingredients that are easily decomposed, fluorescent substances continue to accumulate in the body, greatly weakening the body's own immunity and endangering human health. Fluffy pulp made from waste materials often contains a large amount of toxins. As the cervix of women's uterus is open during menstruation, the fluorescent agents, bleaching agents and toxins on sanitary napkins all penetrate into women's bodies for a long period of time, which may eventually lead to gynaecological inflammation and even cervical cancer. Qualified fluff pulp is actually made from specific wood (wood pulp) that has been processed through a number of processes. The natural wood pulp that is made by putting virgin wood through machine polishing is not suspected of secondary use. material sanitary pads are basically wood pulp, and pumping paper rolls etc. also use bamboo pulp, cane pulp, mixed pulp etc., all of which are natural. By the way, although they can all be tested for quality, obviously, like clothing materials, there are good and bad ones.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China