Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-07

The manufacture of pe breathable film can be divided into blown film method and casting method according to different film-making processes; according to different stretching processes, it can be divided into uniaxial stretching method, biaxial stretching method and local stretching method. Compared with ordinary PE cast embossed film, the manufacture of breathable film has higher technical requirements. In the production process, special attention should be paid to the following aspects:

1.1 Selection of resin

Stiff breathable film - high density polyethylene; flexible breathable film - low density polyethylene; high tensile breathable film - high strength polyethylene; printing (color registration, positioning cutting) - high strength polyethylene

1.2 Selection of calcium carbonate

Surface treatment of calcium carbonate: fluidity, extrusion stability, die coking, pinholes, film mechanical properties, etc.

Selection of calcium carbonate particle size: tensile properties, moisture permeability, uniformity, processability

The selection of raw materials directly affects the processability of the breathable film (such as coking time, extrusion stability, the manufacturability of thin film materials and pinhole defects, etc.) and physical properties (such as air permeability, water pressure resistance, thermal stability and mechanical properties) Wait). Therefore, it is the first consideration when choosing a breathable material to suit the user's physical property requirements for the film and the matching status with the processing equipment

The high humidity of the raw material is the main cause of holes in the breathable film and coking of the T film, which will seriously affect the production efficiency and product quality of the breathable film. Therefore, the production of breathable film should not only dehumidify raw materials (<250ppm), but also have strict humidity control requirements for raw material transportation and flash recovery systems;

Stretching has a magnifying effect on the deviation of extrusion thickness, so the control of extrusion thickness is the premise to ensure the thickness uniformity of the final product;

There are two necessary conditions for the manufacture of breathable film, one is calcium carbonate, and the other is stretching. Therefore, stretching is crucial in the manufacture of breathable membranes. The stretching temperature, stretching ratio, stretching rate and stretching gap are the four elements of the stretching process. Its overall balance will have a great impact on the air permeability, mechanical properties, consistency and appearance of the breathable film;

Using the method of heat treatment to restore and relax the rigid polymer segment after stretching is a necessary means to improve the stability of the breathable membrane material in the subsequent process and use.

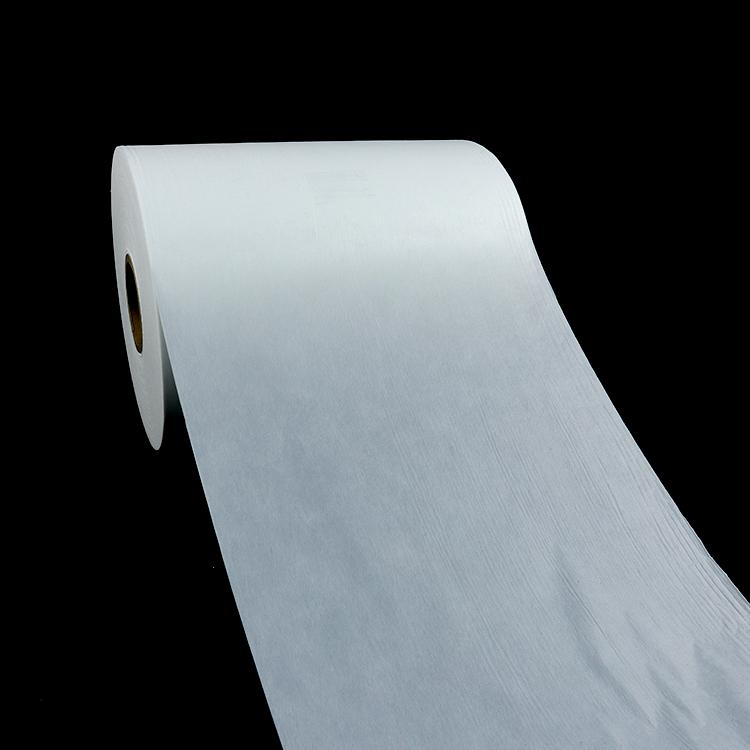

Pe breathable film is used in diapers, sanitary napkins, medical mattresses, etc. There has always been a stable demand in Europe and the United States and other countries, and the domestic sanitary material market is bound to mature with the demand for functionality and comfort. The demand space is bound to increase.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China