Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-19

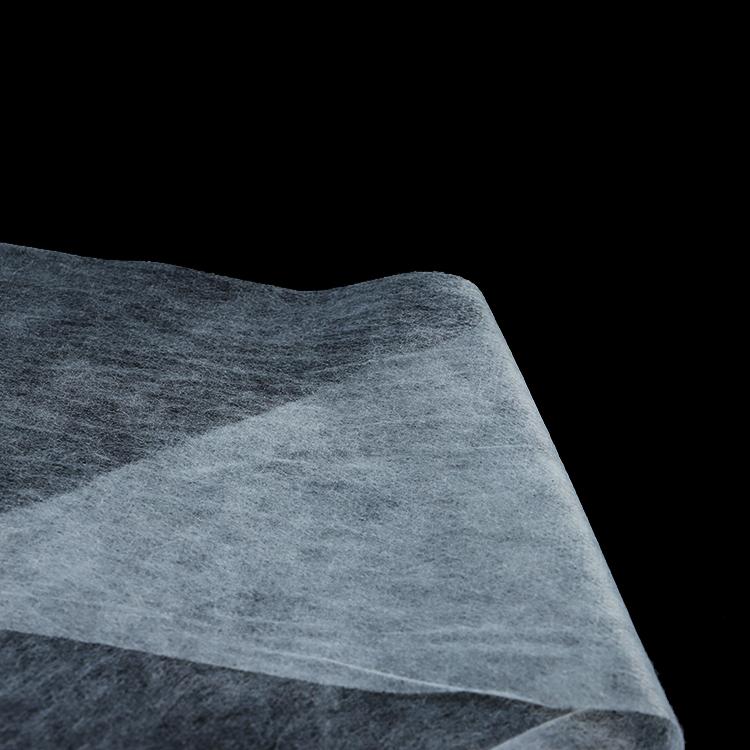

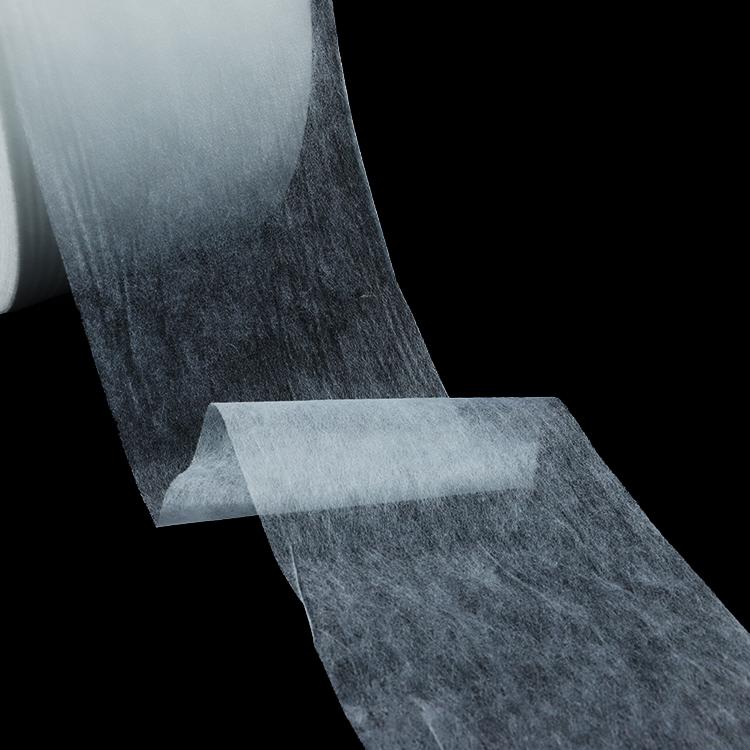

Because PP spunbond non woven fabric has the characteristics of good product performance, low cost and wide application, it has been rapidly developed worldwide. This paper briefly introduces the production process of PP spunbond non-woven fabrics.

Slicing→(drying→)screw extruder melting→filtering→metering→spinning→air drafting→splitting and laying→reinforcing (hot rolling, acupuncture, hydroentanglement or chemical bonding, etc.)→cutting and winding→ finished product

No drying is required when processing PP slices.

After the dried polymer chips are added to the raw material hopper 1 (see the figure), they enter the heated screw extruder 2, and the chips are heated into a melt and then extruded by the screw of the extruder. The spinning device 5 is extruded into a filament stream 7 from the small holes of the spinneret, and then enters the quenching chamber 6, and cold air enters from both sides to cool the hot melt filament stream into filaments. , and then enter the drafting device 8, stretched by high-speed air flow, laid on the mesh curtain belt 9, and then transported to the reinforcement device 10, through hot rolling, chemical bonding, acupuncture, hydroentanglement and other methods. Any one or two methods of reinforcement, that is, the finished spunbond nonwoven fabric.

Spunbond is generally divided into four main processes: spinning, stretching

, web forming, and reinforcement. These four processes are all in one production line, and spinning, stretching and web forming are done in a very short time. completed continuously. Among them, the spinning process is transplanted from the chemical fiber production method; the stretching and web forming process is the core technology of the spunbond process, and it is the embodiment of the process characteristics and technical level. The principle of the stretching device is based on the ejector theory, and its structure is the most important and critical. It is the heart of the spunbond process, which is decisive for the spinning fineness, energy consumption, internal appearance quality, and even the production line capacity and technical level.

With the development and progress of society, people's awareness of hygiene and health is increasing, and PP spunbond non-woven fabrics are more and more widely used in the field of disposable hygiene products. Understanding its production process will help people better understand this non-woven material.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China