Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-15

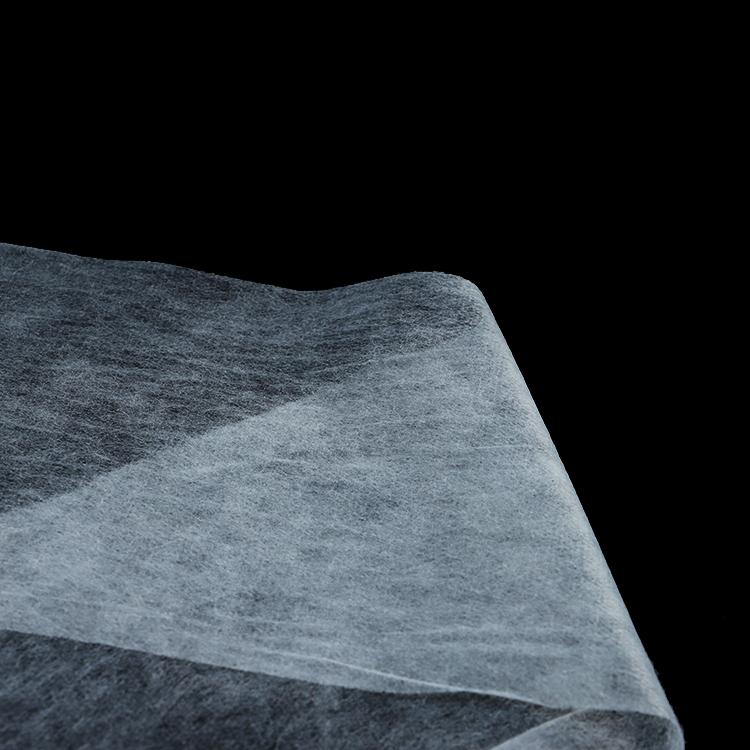

In recent years, due to the short production process, high production efficiency, excellent product performance and wide application range of spunbond nonwovens technology, it caters to the development of nonwovens products in the world today towards high performance and thinness. Therefore, in the process, equipment, Product quality and production cost have been greatly improved and improved. This article mainly introduces the process principle of Small ear spunbond non woven.

The spunbonding method is also the melt spinning method, which uses the principle of chemical fiber spinning to cool the extruded melt filaments through quenched air during the polymer spinning forming process, so that the filaments During the cooling process, it is stretched by the stretching airflow to form continuous filaments, and then formed into a net on the condensed net curtain, and laid on the net-forming curtain, and then processed by a consolidation device to form a spunbonded nonwoven fabric. . The basic process of spunbonded nonwovens includes chip drying, feeding, melt extrusion, spinning, cooling and stretching, splitting and web reinforcement. Among them, the four processes of spinning, cooling drawing, splitting and web reinforcement are in one production line. Spinning, cooling drawing and web forming are completed continuously in a short time. Drawing and The web forming process is the core of spunbond nonwovens technology, which can reflect the level of spunbond technology.

Air draft is a distinctive feature of spunbond nonwovens technology that is different from general processing of chemical fibers. In the stretching channel of the spunbond equipment, because the airflow velocity is much greater than the velocity of the filament extruded from the spinneret hole, the frictional resistance of the filament to the airflow is the main force acting on the filament, and the filament is in contact with the airflow Accelerate under the action of the frictional force, and reach the maximum speed at the slit, so the stretching of the thread is completed between the spinneret and the slit, and the thread is not only completed under the action of the airflow The drafting, and the structure of the fiber has also changed, improving the crystallinity and orientation of the fiber.

Understanding the process principle of Small ear spunbond non woven will help people better understand spunbond nonwovens and help better study the industry

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China