Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-15

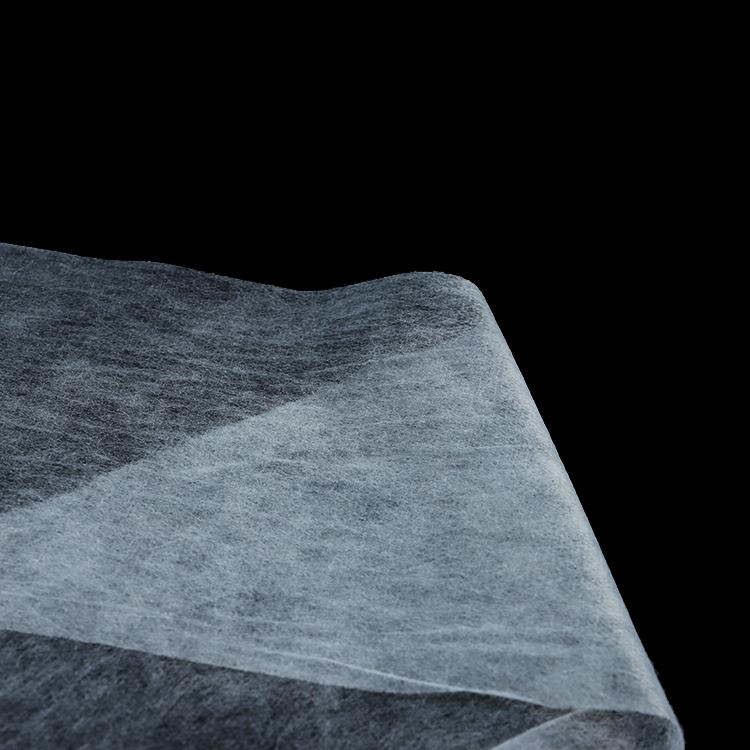

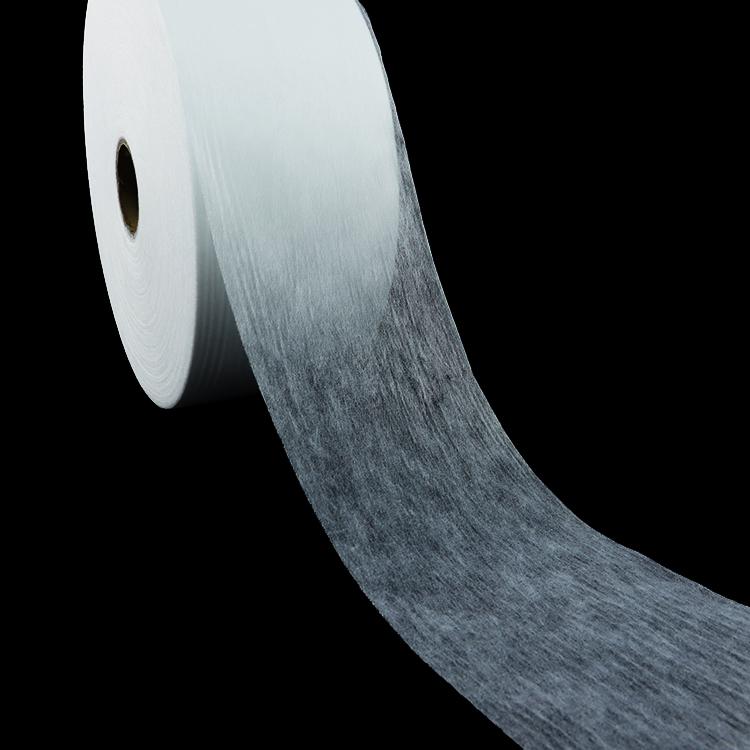

The doubling of the water proof spunbond non woven fabric production line refers to the phenomenon that many fibers are entangled together during the process from spinning to forming a non-woven fabric, causing the filament bundles to be consolidated on the surface of the non-woven fabric. In addition to the cohesion and doubling of the primary yarn due to poor quenching air cooling during spinning, there are three main places in the production line where doubling will occur: the nozzle tunnel, the spinning device and the net curtain of the web forming machine. This article introduces the doubling on the mesh curtain of the web forming machine in the water proof spunbond non woven fabric production line.

There are three methods of doubling wires on the net curtain of the net forming machine: one is to form parallel wires on the net curtain and roll on the net curtain like a cat's tail; The surface layer of the flakes on both sides of the net curtain at the rear of the web forming machine is flanged. Strictly speaking, the latter two cases do not belong to doubling, but the effect is the same as that of doubling, which affects the surface quality of non-woven fabrics.

The parallel phenomenon on the net curtain of the net forming machine is caused by the unbalanced air flow between the upper and lower sides of the net curtain of the net forming machine.

The drafting power of water proof spunbond non woven fabric is air (called the mainstream), the mainstream flow and the flow flow that is drawn into the inside of the nozzle are ejected from the outlet of the nozzle and shot to the net curtain of the web forming machine. The air volume should pass through the flakes and net curtains and enter the suction air duct of the web forming machine, and be discharged after being pressurized by the air-conditioning fan. It often happens that the air volume injected by the nozzles on the net curtains is large, and the air volume sucked by the air-conditioning room is small. , the excess air engulfs the floating filaments on the upper layer of the flakes along the surface of the net curtain to form a cat-tail-shaped tow that flows forward and backward, resulting in parallel filaments. In order to balance the air volume above and below the net curtain, the suction volume of the fan in the air-conditioning room can be increased. The suction volume includes the air volume ejected from the nozzle, and also includes the supplementary air from the net curtain at the rear of the web forming machine and The supplementary air on both sides of the net curtain at the rear of the web forming machine, the latter two supplementary air will cause the flakes to turn over and turn over. For web forming machines similar to the NWT production line, even if the air volume is balanced, it is difficult to avoid doubling, web turning and flanging on the web forming machine. When the linear speed of the web forming machine increases, even if the surrounding air is still, when the speed of the fluffy flakes relative to the still air is greater than a certain value, the net will be turned over. Referring to the STP web-laying machine, the NWT web-forming machine is modified. The main air duct of the web-laying machine is divided into several units, and the pressure can be adjusted separately. A pair of heated air ducts is added at the boundary of the main and auxiliary air duct Pre-compression rollers are especially effective in preventing doubling, turning over and flanging on the screen. The flakes that have been pressed are equivalent to being ironed, and are not easy to turn over and turn over, which can greatly improve the surface quality of non-woven fabrics and increase production speed.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China