Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-06-08

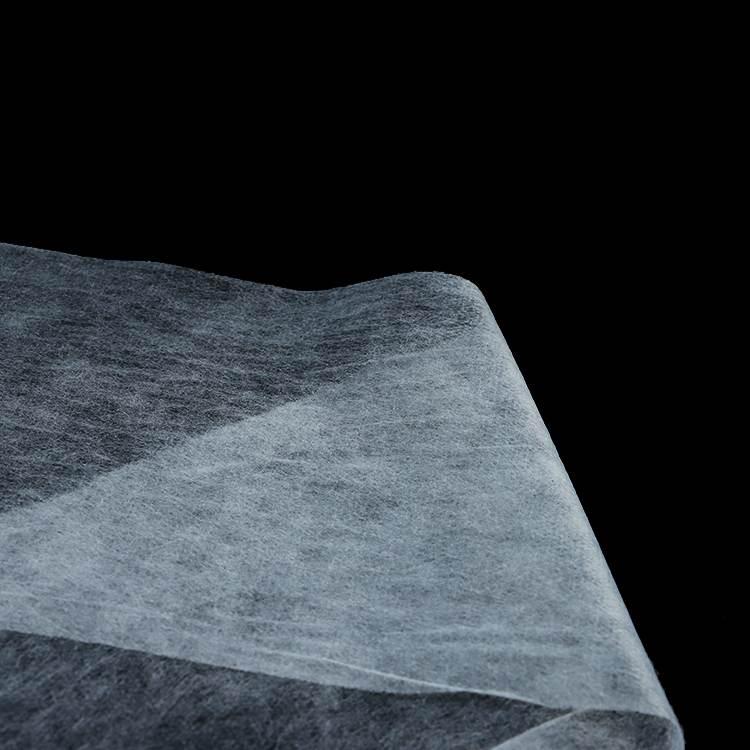

In the manufacturing of disposable diapers, one of the most important materials used is non-woven products. Non-woven fabrics are manufactured by bonding fibers together mechanically, thermally or chemically, without using weaving or knitting methods. They offer a number of advantages over traditional woven fabrics such as their high strength, low cost, absorbency, and softness. In this article, we will explore the use of non-woven products in the manufacture of disposable diapers.

Non-woven products are made from fibers that are bonded together using various methods. The fibers can come from synthetic materials such as polypropylene or polyester or natural materials such as cotton, wool, or silk. These fibers are bonded together using mechanical, thermal or chemical processes to create a strong and durable fabric. Non-woven fabrics are commonly used in the manufacturing of disposable products such as diapers, sanitary napkins, and medical gowns.

Non-woven fabrics play a critical role in the manufacturing of disposable diapers. They are used in all the components of a diaper including the outer cover, inner lining, and absorbent core. The outer cover of a diaper is made from a breathable and waterproof non-woven material that helps to prevent leaks. The inner lining is also made from a soft non-woven material that provides comfort to the baby's delicate skin. Finally, the absorbent core is composed of several layers of non-woven fabrics that absorb the liquid and prevent it from leaking out of the diaper.

There are several advantages of using non-woven products in the manufacturing of disposable diapers. First, non-woven fabrics are lightweight and easy to work with, which makes them ideal for use in fast-paced manufacturing environments. Second, they are highly absorbent, which means they can hold large amounts of liquid without leaking. Third, non-woven fabrics are soft and gentle on the skin, making them comfortable for babies to wear. Fourth, non-woven fabrics are cost-effective, which helps to keep the price of disposable diapers affordable for consumers.

In conclusion, the use of non-woven products in the manufacture of disposable diapers provides several advantages over traditional woven fabrics. These materials are lightweight, absorbent, soft, and cost-effective, which makes them ideal for use in fast-paced manufacturing environments. As the demand for disposable diapers continues to grow, non-woven fabrics will remain an essential component in their production.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China