Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-20

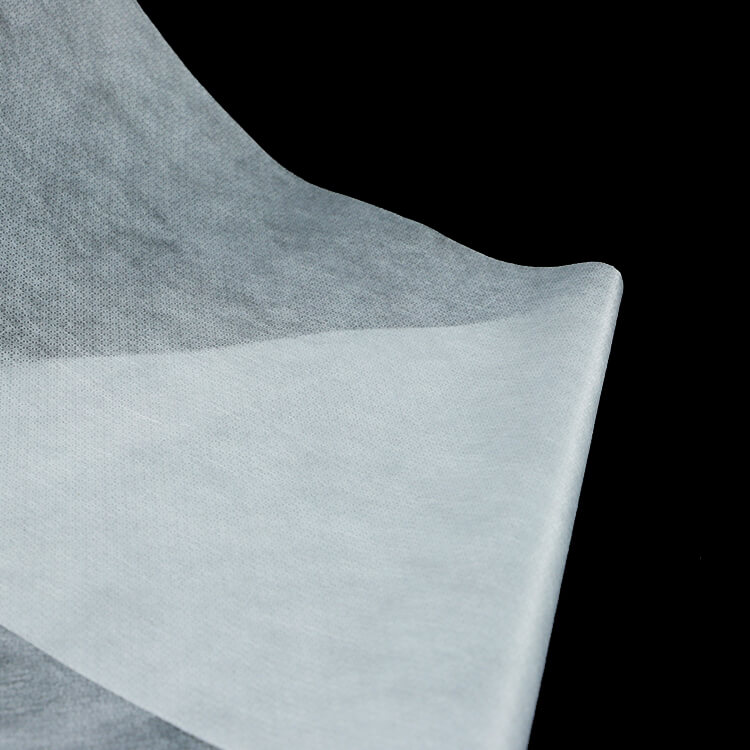

Driving Innovation in Diapers with Leak Guard SMMS Meltblown Nonwoven Fabric

Diapers have come a long way since their invention, and one of the key components that has revolutionized the industry is the leak guard technology. Leak guards are crucial in preventing leakage and providing enhanced comfort for babies. In recent years, there has been a significant development in the field of diaper manufacturing, particularly with the use of SMMS (Spunbond-Meltblown-Meltblown-Spunbond) meltblown nonwoven fabric. This article explores how this innovative fabric is driving change and improving the performance of diapers.

One of the primary reasons why SMMS meltblown nonwoven fabric is being increasingly used in diapers is its exceptional absorbency capabilities. The fabric is designed to quickly absorb and distribute liquid, locking it away from the baby's skin, thus minimizing the risk of leakage. This advanced technology ensures that the baby remains dry and comfortable, allowing for uninterrupted play and sleep. Moreover, the fabric's ability to effectively manage large volumes of liquid reduces the frequency of diaper changes, offering convenience and cost savings for caregivers.

In addition to its absorbency benefits, SMMS meltblown nonwoven fabric also offers improved softness and breathability compared to traditional diaper materials. The fabric is composed of super-fine fibers that are more delicate and gentle against the baby's skin, reducing the likelihood of irritation or discomfort. Furthermore, the fabric's structure allows for enhanced air circulation, preventing the buildup of heat and moisture, which can lead to skin rashes. The combination of softness and breathability ensures that the baby's skin remains dry, fresh, and healthy, even during prolonged use.

Another notable advantage of SMMS meltblown nonwoven fabric is its positive impact on environmental sustainability. Traditional diapers often contribute to landfill waste due to their slow degradation process. However, the use of SMMS meltblown nonwoven fabric promotes eco-friendliness as it is biodegradable and breaks down more rapidly. This feature reduces the environmental footprint of diaper disposal and aligns with the growing global concern for sustainable practices. Manufacturers are increasingly recognizing the importance of incorporating environmentally friendly materials into their products, and SMMS meltblown nonwoven fabric presents a viable solution in this regard.

The adoption of SMMS meltblown nonwoven fabric in diaper manufacturing has transformed the industry by driving innovation and delivering superior performance. With its enhanced absorbency, leakage protection, softness, breathability, and environmental sustainability, this fabric has revolutionized the way diapers are designed and produced. As technology continues to evolve, it is likely that we will witness further advancements in the field of diapers, providing even better comfort and protection for babies while minimizing the impact on the environment.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China