Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-24

Unleashing the Potential of Hydrophobic SMMS Non Woven Fabric in Diaper Production

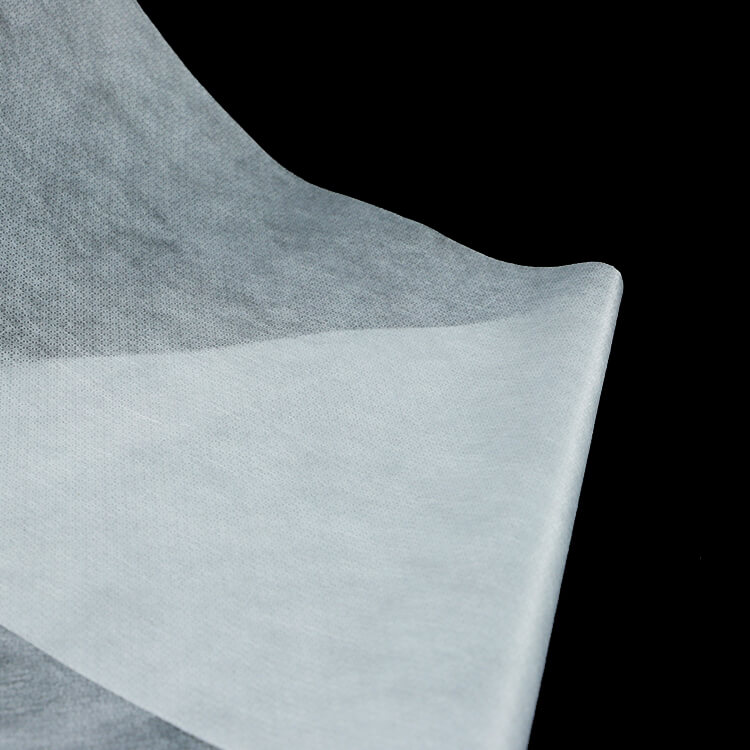

The use of non woven fabrics in diaper production has revolutionized the industry, providing enhanced comfort, absorption, and leak protection. Among these non woven fabrics, hydrophobic SMS (Spunbond-Meltblown-Spunbond) has gained significant attention. This article aims to explore the potential of hydrophobic SMMS non woven fabric in diaper production and highlight its advantages over traditional materials.

Hydrophobic SMMS non woven fabric offers superior performance in terms of liquid management. The incorporation of a hydrophobic agent during the manufacturing process makes the fabric water-resistant, preventing liquid penetration. This feature ensures that the diaper remains dry, reducing the risk of skin irritation and discomfort for the wearer. Additionally, the fabric's breathability allows for better air circulation, keeping the baby's skin fresh and preventing rashes.

In comparison to traditional materials, hydrophobic SMMS non woven fabric exhibits enhanced absorbency. The meltblown layer in the fabric traps liquids effectively, while the spunbond layers provide structural integrity and prevent leakage. The combination of these properties results in a diaper that can handle higher fluid volumes, reducing the frequency of changes and enhancing convenience for parents. Moreover, the excellent liquid retention capacity of SMMS fabric prevents rewetting, ensuring the baby stays dry for longer periods.

Another advantage of hydrophobic SMMS non woven fabric is its eco-friendly nature. The manufacturing process involves minimal water consumption compared to traditional textiles, reducing the strain on water resources. Additionally, the fabric is biodegradable, contributing to the reduction of landfill waste. By using hydrophobic SMMS non woven fabric in diaper production, manufacturers can align their products with sustainable practices, appealing to environmentally conscious consumers.

The utilization of hydrophobic SMMS non woven fabric in diaper production offers numerous benefits, including enhanced performance, improved absorption, leak protection, and environmental sustainability. This innovative fabric provides a higher level of comfort for babies, reduces the frequency of diaper changes, and contributes to a greener future. As the industry continues to evolve and prioritize the well-being of both babies and the environment, incorporating hydrophobic SMMS non woven fabric in diaper production is a step towards meeting these demands. Manufacturers should seize the potential of this fabric to create diapers that excel in performance, comfort, and sustainability.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China