Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-30

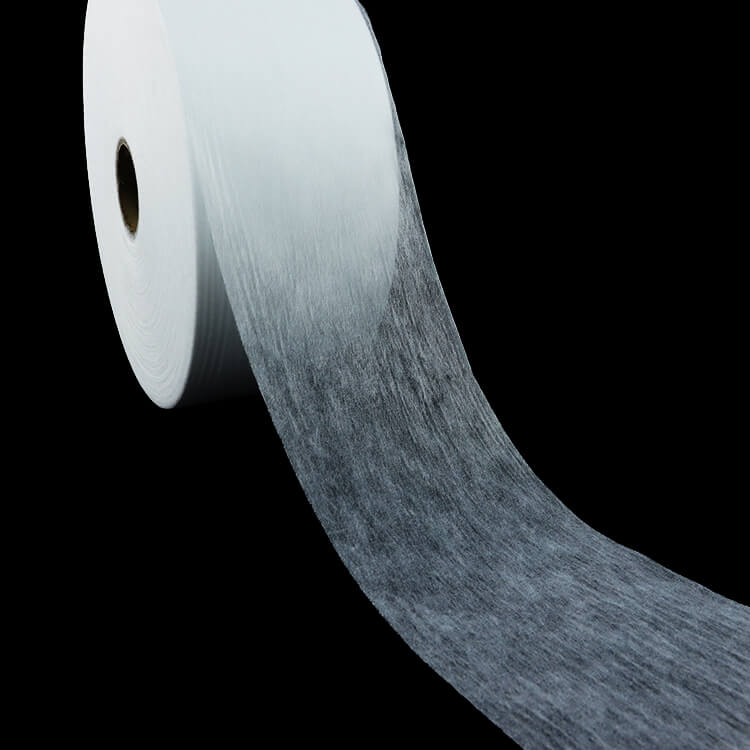

Enhancing Diaper Efficiency with Printed Spunbond Materials

The use of diapers is a necessity for infants and toddlers, providing comfort and hygiene. However, the efficiency of diapers can be further improved to enhance the overall experience for both the wearer and caregiver. One promising solution lies in the utilization of printed spunbond materials. In this article, we will explore the benefits and potential of using printed spunbond materials to enhance the efficiency of diapers.

One of the key advantages of using printed spunbond materials in diapers is their enhanced absorbency. Spunbond fabrics are known for their ability to rapidly wick away moisture, preventing the skin from becoming damp or irritated. By incorporating printed designs onto the spunbond layer, the absorbency of the diaper can be further optimized. The printed patterns can create micro-channels within the fabric, allowing for a more efficient distribution of liquid throughout the diaper. This ensures that the absorbent core is utilized to its fullest potential, reducing the risk of leakage and improving overall comfort.

Moreover, printed spunbond materials can be engineered to have varying levels of absorbency in different regions of the diaper. For example, areas that are prone to higher wetness, such as the front or back, can be designed to have higher absorbency, while areas that come into contact with the baby's delicate skin can be made softer and less absorbent. This targeted absorbency distribution not only enhances the efficiency of the diaper, but also improves the overall user experience by providing customized comfort.

Another aspect where printed spunbond materials excel is in improving the fit and comfort of diapers. Traditional diapers often feature plain, monotonous designs, lacking visual appeal. By incorporating printed patterns onto the spunbond layer, diapers can be transformed into visually appealing products that are more enjoyable for both parents and children. Additionally, the printing process allows for the creation of stretchable materials, ensuring a snug fit around the baby's waist and legs without sacrificing comfort.

The use of printed spunbond materials also enables the incorporation of moisture indicators within the diaper design. These indicators change color when the diaper is wet, providing a convenient visual cue for caregivers to know when it is time for a change. This feature not only enhances convenience but also helps prevent discomfort for the wearer, as timely diaper changes can greatly reduce the risk of diaper rash and skin irritation.

Aside from the functional benefits, the use of printed spunbond materials in diapers can also have positive environmental implications. Spunbond fabrics are typically made from polypropylene, a material that is recyclable and has a lower environmental impact compared to other plastics used in diapers. By utilizing printed spunbond materials, diaper manufacturers can potentially reduce waste and promote sustainability in the industry.

Furthermore, the printing process itself can be optimized to minimize water and energy consumption, further reducing the environmental footprint of diaper production. With an increasing emphasis on eco-friendly practices, incorporating printed spunbond materials into diapers aligns with the growing demand for sustainable and environmentally-conscious products.

In conclusion, the use of printed spunbond materials in diapers holds great potential for enhancing their efficiency. Through improved absorbency, enhanced fit and comfort, and environmental considerations, printed spunbond materials offer numerous advantages that contribute to a better overall diaper experience. As diaper technology continues to advance, embracing innovative solutions like printed spunbond materials will undoubtedly lead to more efficient and sustainable products in the future.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China