Price:negotiable

Delivery time: 15-20 days after receiving deposit or LC.

Payment terms: TT/LC/DP

Application: Sanitary napkin,Baby diaper,Adult diaper

Minimum order quanity: 1000.00 kgs

Packing details: Paper board with transparent film

Hydrophobic spunbond non woven fabric features:

1) Our products are nontoxic,pollution-free,clean,and tensile

2) Soft and confortable

3) Printing: Printed and non-printed

4) We can provide the competitive price and higher qual

Application:

Disposable personal healthcare products

Women's sanitary napkins,saniatry pads,baby diaper,adult diaper and underpads

Disposable medical protection products

|

Product Name |

hydrophobic nonwoven |

|

Nonwoven Technics |

SpunBond |

|

Material |

100% Polypropylene |

|

Product Usage |

Baby diaper, sanitary napkin, adult diaper and undder pad |

|

Feature |

Anti-bacterial, Anti-static, Anti-UV, Fireproof, Waterproof, Hydropilic, Laminated(pp+pe), Printed, Preforation,etc. |

|

Gram Weight |

9gsm-100gsm |

|

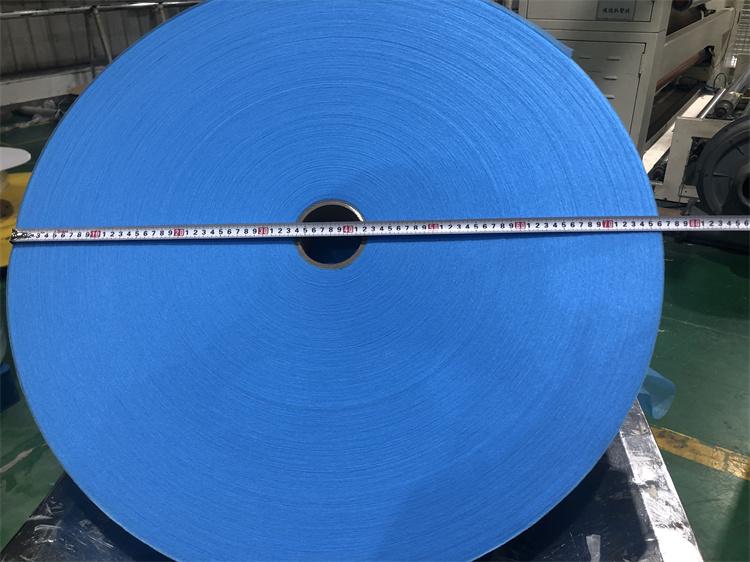

Width |

Max 320cm at present, can be slitting as customer's requirement |

|

Tensionble test |

Elongation-MD(%):targe80-Max130 |

|

Printing |

Various design available or customized |

|

Color |

As per customer's requirement |

|

Packing |

Paper board with transparent film |

|

sample |

free |

Acquisition distribution layer ADL nonwoven fabric roll features: 1. Accelerate the absorption of urine bythe core 2. Make the diaper evenly thick afterabsorbing water ...

ADL Nonwoven Fabric is developed withairthrough bonded technology to be used for the production of baby diapers,sanitary napkins and incontinence diapers. ADL non woven features...

Spunlacenon woven fabric in hygiene field mainly used for top sheet of variousdisposable sanitary products( sanitary napkins, panty liners, baby / adultdiapers, wet tissues, etc). ...

ADL non woven fabric can be called Acquisition Distribution Layer ADL, It is a kind of hot air non woven fabric, made by ES fabric. There are some advantages of ADL non woven fabr...

In the highly competitive market for personal care products in Brazil, customers are always looking for ways to stand out and gain an edge over their competitors. One way to do thi...

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China