Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-07

Unveiling the Versatile Applications of Spunbond Meltblown in Diaper Production

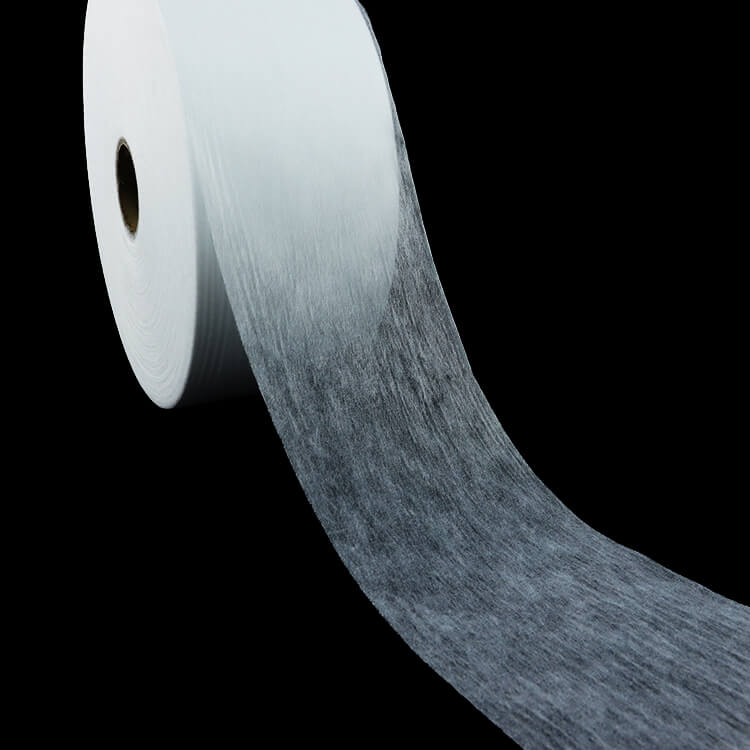

Diapers are an essential product for infants and toddlers, providing convenience and comfort to both parents and children. Over the years, diaper manufacturers have constantly strived to improve their products, focusing on enhancing absorbency, breathability, and overall performance. One of the key technologies revolutionizing the diaper industry is spunbond meltblown nonwoven fabric. This innovative material has found versatile applications in diaper production, resulting in significant improvements in terms of comfort, leakage prevention, and environmental impact.

Traditional diapers often had a plastic-like feel due to the use of materials such as polyethylene film and polypropylene nonwoven fabric. However, with the integration of spunbond meltblown fabric, diapers now offer enhanced comfort and softness. Spunbond meltblown fabric is known for its fine fibers, which create a smooth and gentle surface that is gentle on the delicate skin of babies. The fabric also provides excellent breathability, allowing for better air circulation and reducing the risk of diaper rash.

Another important application of spunbond meltblown in diaper production is its contribution to improved absorbency and leakage prevention. The unique structure of spunbond meltblown fabric allows for better liquid retention and distribution. The meltblown layer acts as a barrier, preventing the liquid from seeping back to the surface, while the spunbond layer facilitates the rapid absorption and dispersion of the liquid. This dual-layer construction ensures that the diaper remains dry and prevents leakage, providing a secure and comfortable experience for babies and peace of mind for parents.

With increasing environmental concerns, the diaper industry has been striving to reduce its ecological footprint. Spunbond meltblown fabric offers a more sustainable alternative to traditional materials. Firstly, the production process of spunbond meltblown nonwoven fabric consumes less energy and generates fewer greenhouse gas emissions compared to the production of plastic films. Additionally, the fabric is biodegradable and can be incorporated into eco-friendly diaper designs that minimize waste and promote recycling. By using spunbond meltblown in diaper production, manufacturers are taking a step towards a greener and more environmentally friendly future.

The versatile applications of spunbond meltblown in diaper production have significantly improved the quality, comfort, and sustainability of diapers. The integration of this innovative fabric has resulted in enhanced comfort and softness, improved absorbency and leakage prevention, and a more environmentally friendly approach to diaper manufacturing. As technology continues to advance, we can expect further innovations in the diaper industry, driven by materials like spunbond meltblown fabric. Ultimately, these advancements will continue to benefit both parents and babies, providing them with better diaper options that prioritize comfort, performance, and sustainability.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China