Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

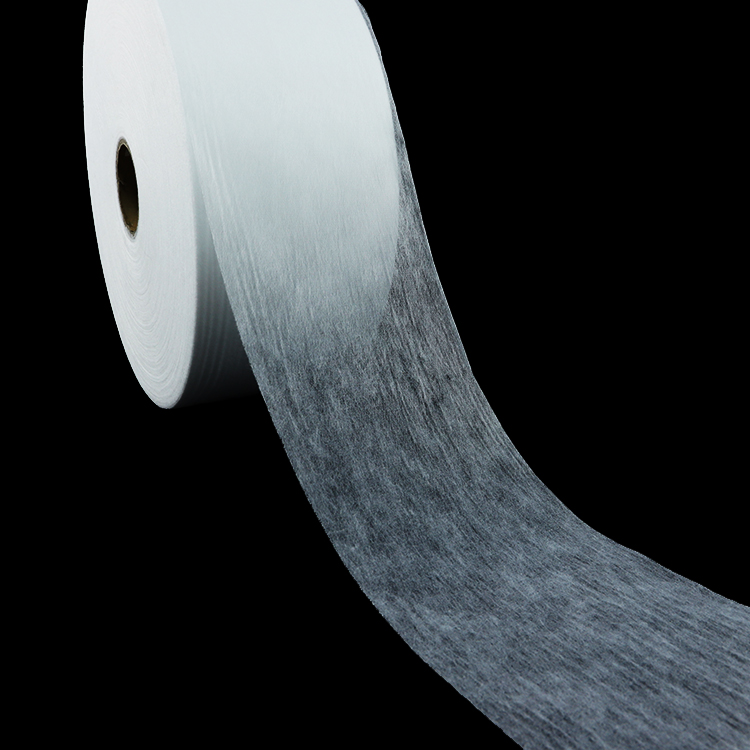

Effective Core Construction with Thermal Bonding in Non-woven Materials for Diapers

In the world of baby care products, diapers play a vital role in ensuring comfort, dryness, and hygiene for infants. The core of a diaper is responsible for absorbing and retaining liquid waste, distributing it evenly, and preventing leakage. Traditionally, cores were constructed using fluff pulp, which has limitations in terms of bulkiness and slow absorption. However, with advancements in technology, non-woven materials with thermal bonding have emerged as an effective alternative for diaper cores.

The first significant advantage of using non-woven materials with thermal bonding in diaper cores is enhanced absorbency. Thermal bonding involves the process of applying heat and pressure to fuse fibers together, creating a cohesive structure. This bonding creates a network of interconnected fibers that improves liquid distribution, thereby maximizing the absorbency capacity of the core. The uniformity obtained through thermal bonding ensures every part of the core contributes equally to absorbency, reducing the risk of leaks and keeping the baby's skin dry.

Another benefit of utilizing thermal bonding in non-woven materials for diaper cores is the reduction in bulkiness. Fluff pulp-based cores tend to be thick and bulky, making it uncomfortable for babies to move freely. On the contrary, non-woven materials enable the creation of thinner cores without compromising absorbency. The thermal bonding process allows for controlled fiber placement, which helps in achieving a compact and thin core structure. This reduced bulkiness ensures a comfortable fit for the baby, allowing for unrestricted movement and better overall comfort.

Thermal bonding in non-woven materials also enhances the structural integrity and leakage prevention capabilities of diaper cores. The cohesive network created by thermal bonding improves the core's strength, preventing it from falling apart even when saturated with liquid waste. This added strength minimizes the risk of sagging, clumping, or shifting, ensuring that the core remains intact and maintains its shape. Additionally, the thermal bonding process creates a barrier within the core, preventing liquid from re-wetting the surface, and reducing the chances of leakage.

In conclusion, the use of non-woven materials with thermal bonding in diaper cores offers numerous advantages over traditional fluff pulp cores. Enhanced absorbency, reduced bulkiness for enhanced comfort, and enhanced structural integrity and leakage prevention are some of the key benefits of this innovative construction method. These advancements improve the overall performance of diapers, providing babies with increased dryness, comfort, and protection. With the continuous advancement of technology, we can expect further refinement and optimization in the construction of diaper cores, ensuring the best possible experience for both infants and caregivers.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China