Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

Unleashing the Power of Hydrophilic Thermal Bond Non Woven Fabric in Diaper Manufacturing

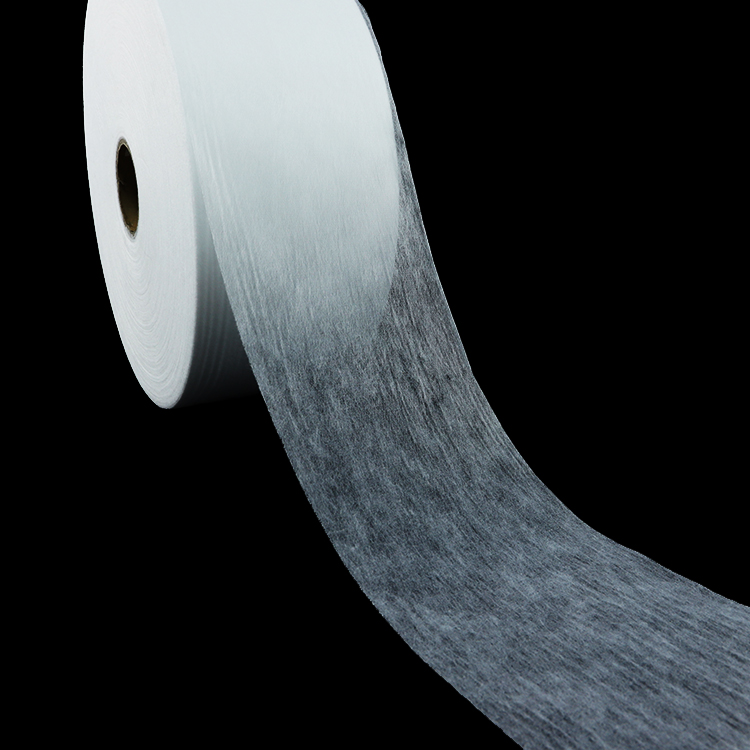

In the world of diaper manufacturing, innovation is key to meet the ever-evolving needs of parents and caregivers. One such groundbreaking innovation is the use of hydrophilic thermal bond non-woven fabric. This fabric has revolutionized the diaper industry by offering superior absorption, breathability, softness, and comfort for babies. In this article, we will explore the various advantages and applications of hydrophilic thermal bond non-woven fabric in diaper manufacturing.

The first and most important advantage of hydrophilic thermal bond non-woven fabric is its superior absorption properties. This fabric is designed to quickly absorb and lock away moisture, keeping the baby's skin dry and preventing discomfort and irritation. The hydrophilic nature of the fabric allows it to attract and retain liquid, ensuring that the baby stays comfortable and protected from leaks. Additionally, the thermal bonding process enhances the fabric's ability to hold a significant amount of liquid without compromising its integrity.

Compared to traditional fabrics used in diapers, hydrophilic thermal bond non-woven fabric offers a higher absorption capacity, reducing the need for frequent diaper changes. This not only saves time for parents and caregivers but also reduces the environmental impact of diaper disposal.

Babies have delicate and sensitive skin that requires proper airflow to prevent rashes and irritation. Hydrophilic thermal bond non-woven fabric provides enhanced breathability due to its unique structure. The fabric is composed of small, interconnected fibers that create microchannels for air circulation. This allows for better ventilation and moisture evaporation, reducing the risk of diaper rash and maintaining the baby's skin health.

The breathability of this fabric also contributes to a more comfortable wearing experience for the baby. It prevents the build-up of heat and humidity, keeping the diaper area cool and dry. As a result, the baby is less likely to become fussy or uncomfortable, promoting a better overall sleep quality and mood.

Hydrophilic thermal bond non-woven fabric is known for its exceptional softness and comfort, making it ideal for diaper manufacturing. The fabric is gentle against the baby's delicate skin, minimizing the risk of friction and irritation. It provides a cushioning effect, giving the baby a cozy feeling even during prolonged use.

Moreover, the softness of this fabric enhances the overall fit and flexibility of the diaper. It molds to the baby's body, ensuring a snug and secure fit without restricting movement. This allows the baby to move freely and comfortably, promoting healthy physical development.

Hydrophilic thermal bond non-woven fabric has transformed the diaper manufacturing industry by offering superior absorption, breathability, softness, and comfort. Its ability to quickly absorb and lock away moisture ensures that the baby stays dry and protected. The enhanced breathability of the fabric promotes healthy skin by allowing proper airflow and moisture evaporation. Additionally, the softness and comfort of the fabric provide a gentle and secure fit for the baby, ensuring a comfortable wearing experience. With these remarkable advantages, hydrophilic thermal bond non-woven fabric has undoubtedly unleashed a new level of performance in diaper manufacturing.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China