Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-21

Unveiling the Advantages of Thermal Bonding in Non-woven Materials for Diapers

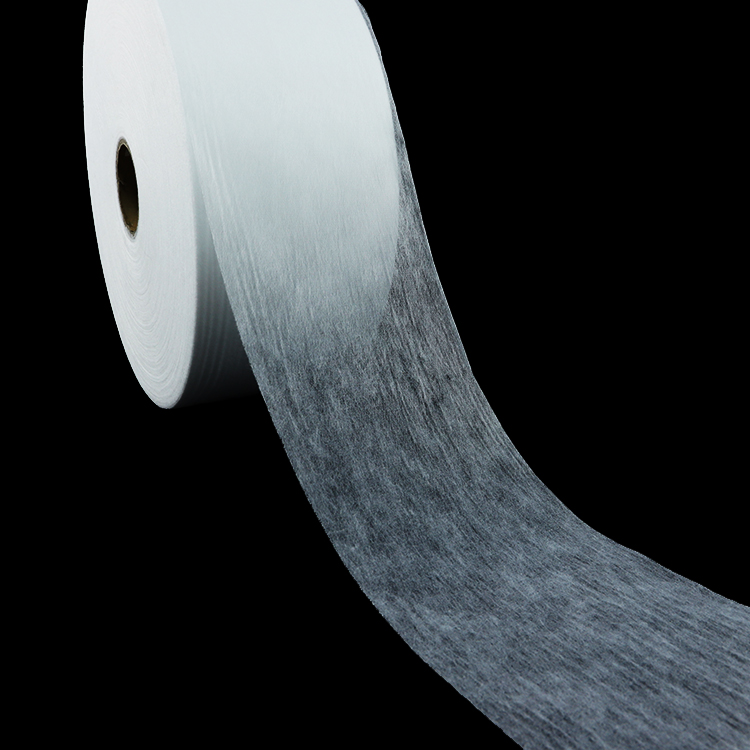

Diapers are an essential product in the lives of infants and toddlers, providing comfort, protection, and convenience. The materials used in diapers play a crucial role in their performance, and non-woven materials have gained popularity due to their excellent properties. Thermal bonding is a commonly used technique in the production of non-woven materials for diapers. This article aims to explore the advantages of thermal bonding and its impact on the quality and functionality of diaper materials.

One of the key advantages of thermal bonding in non-woven materials for diapers is the enhanced softness and comfort it provides. During the thermal bonding process, heat is applied to the fibers, causing them to melt and fuse together. This fusion creates a smoother surface, reducing the friction between the diaper and the baby's delicate skin. The result is a softer and more comfortable diaper, minimizing the risk of irritation or discomfort.

Furthermore, thermal bonding allows for the customization of the material's loftiness and density. By adjusting the temperature and pressure during the bonding process, manufacturers can control the thickness and fluffiness of the non-woven material. This flexibility enables the production of diapers with varying levels of softness, catering to the diverse needs and preferences of different users.

A second advantage of thermal bonding in non-woven materials for diapers is its impact on absorbency and leakage protection. The fusion created through thermal bonding increases the material's integrity and prevents the formation of gaps or loose fibers. This enhanced structural stability ensures that the material retains its shape even when wet, promoting efficient liquid absorption.

Additionally, thermal bonding improves the material's resistance to compression. When pressure is exerted on the diaper, such as when the baby is sitting or lying down, the bonded fibers create a barrier that prevents the liquid from leaking out. This feature is especially important in preventing leakage during prolonged periods of wear, allowing babies to stay dry and comfortable for extended periods.

The third advantage of using thermal bonding in non-woven materials for diapers is its impact on efficiency and production speed. Thermal bonding is a rapid and cost-effective process, making it an attractive choice for manufacturers. The fusion of fibers occurs quickly, reducing the production time required compared to other bonding methods.

Furthermore, thermal bonding eliminates the need for additional adhesives or chemicals commonly used in other bonding techniques. This reduces the complexity of the manufacturing process and eliminates potential chemical-related concerns. The simplicity of thermal bonding also allows for easy scalability, enabling manufacturers to increase production volume without significant investment in equipment or modifications to existing processes.

In conclusion, thermal bonding offers numerous advantages in the production of non-woven materials for diapers. It enhances the softness and comfort of the material, improving the overall experience for babies. Additionally, thermal bonding improves absorbency and leakage protection, ensuring that diapers perform effectively in preventing leaks and keeping babies dry. Lastly, thermal bonding offers enhanced efficiency and production speed, benefiting manufacturers in terms of time and cost savings. With these advantages, thermal bonding continues to be a preferred method in the production of high-quality diaper materials.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China