Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-08-22

Unveiling the Benefits of Thermal Bonded Nonwoven in Diaper Manufacturing

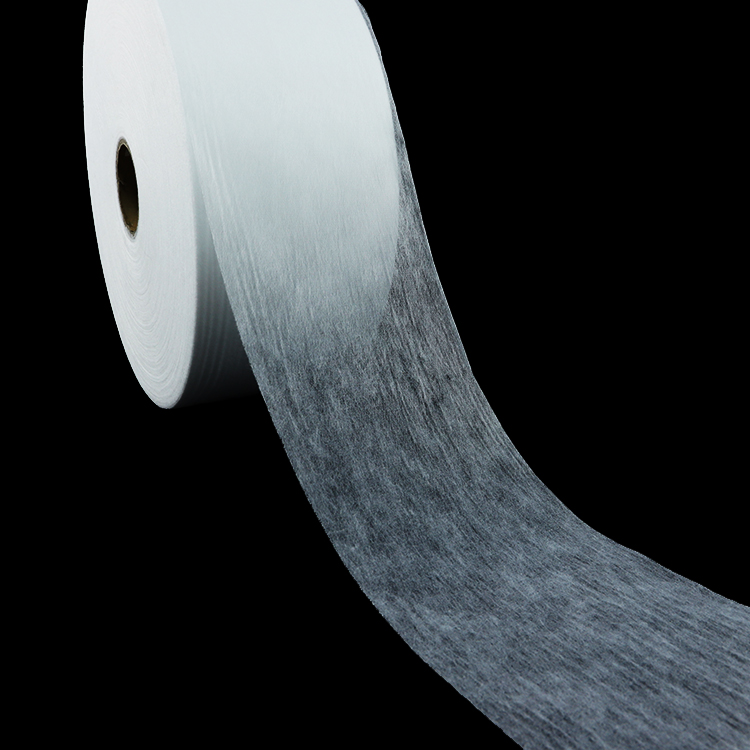

Diapers are an essential product that provides convenience and comfort for infants and toddlers. The manufacturing process of diapers involves various materials, one of which is thermal bonded nonwoven fabric. This article aims to explore the benefits of using thermal bonded nonwoven in diaper manufacturing and how it contributes to the overall quality and performance of diapers.

One of the key advantages of using thermal bonded nonwoven in diaper manufacturing is its enhanced absorbency. The thermal bonding process creates a fabric with a three-dimensional structure, allowing for efficient absorption and distribution of liquids. This significantly reduces the chances of leakage and keeps the baby's skin dry for a longer time.

In addition to absorbency, thermal bonded nonwoven fabric also provides excellent breathability. The unique structure of the fabric allows air to circulate freely, preventing the accumulation of heat and moisture, which can lead to discomfort and skin irritations. By promoting airflow, thermal bonded nonwoven helps maintain a fresh and dry feeling, essential for the baby's comfort.

Another significant benefit of thermal bonded nonwoven fabric in diaper manufacturing is its softness and skin-friendliness. The thermal bonding process creates a fabric with fine fibers, resulting in a gentle and smooth texture. This ensures that the diaper feels soft against the baby's delicate skin, minimizing the risk of irritation and rashes.

Furthermore, thermal bonded nonwoven fabric is hypoallergenic and free from harmful chemicals, making it suitable for even the most sensitive skin. It provides a barrier between the wetness and the baby's skin, preventing irritation and maintaining the skin's natural pH balance. This is crucial for keeping the baby comfortable and healthy.

Thermal bonded nonwoven fabric also contributes to the improved structural integrity of diapers. The thermal bonding process ensures that the fabric maintains its strength even when wet, preventing sagging and ensuring a snug fit. This is important for preventing leakage and providing maximum protection for the baby.

In addition, the thermal bonding process allows for the precise placement of different layers in the diaper structure. This helps optimize the performance of each layer, such as the absorbent core, the acquisition layer, and the outer cover. The result is a diaper that effectively traps moisture, minimizing the risk of leaks and ensuring long-lasting dryness.

Thermal bonded nonwoven fabric plays a crucial role in improving the quality and performance of diapers. Its enhanced absorbency, breathability, softness, and skin-friendliness contribute to the overall comfort and well-being of babies. Furthermore, it provides structural integrity and optimized layer placement, ensuring maximum protection against leaks. With these benefits, thermal bonded nonwoven fabric proves to be an excellent choice for diaper manufacturing, meeting the needs of both babies and parents.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China