Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-03

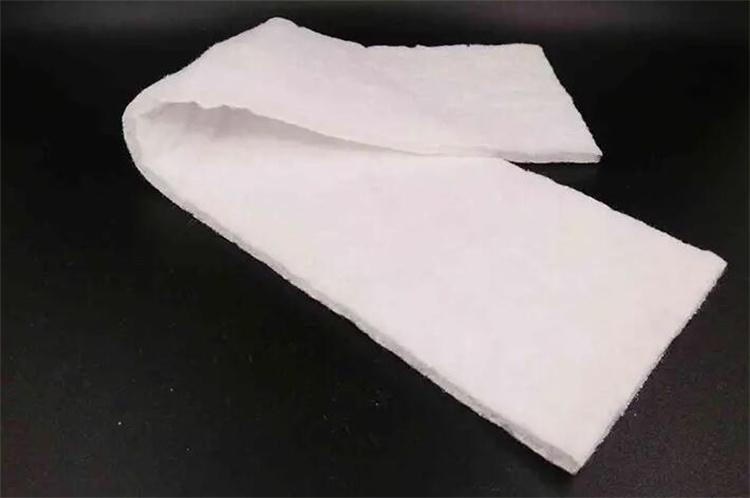

Airlaid sap paper is a key factor in determining the comfort of diapers. This article briefly introduces the innovation and development of diaper airlaid sap paper.

At present, both foreign and domestic brands, traditional fluff pulp airlaid sap paper or new composite cores, are constantly innovating processes to develop lighter, thinner and more comfortable, more liquid-absorbing and anti-reverse osmosis effects. A good product with no lumps, making it easy to wear.

For example, the core of a diaper developed by Kimberly-Clark is composed of three layers of SAP and fluff pulp mixed core. The thickness of each core is increasing, and there is at least one longitudinally extending channel in the surface core to disperse urine. The liquid absorption speed is fast, and it can keep the surface of the diaper dry and breathable.

Smart diapers are also in development.

For example, the patent CN201480070386.1 of Kimberly-Clark Corporation discloses a urine odor control system for personal care products, which includes a base of activated carbon formulation and an absorbent core of silver formulation.

American Curiosity also launched a concept diaper, which placed the moisture sensor in the airlaid sap paper of the diaper. When the sensor detects the change of the moisture content in the diaper, it will send a message to the parents through the APP to remind the parents to change the diaper in time.

By reducing the amount of fluff pulp added, the absorbent core is lighter and thinner, which is also the development direction of modern diapers.

For example, a diaper from Hengan Group has been upgraded with dual core technology. The upper layer is an integrated woven core of dust-free paper and hot air fluffy non-woven material wrapping SAP, and the lower layer is traditional airlaid sap paper. The composite of the two cores greatly reduces the original absorbent thickness. And the amount of SAP added is as high as 65.00%. It can absorb up to 560 mL of urine, with increased liquid absorption, and the core structure does not agglomerate or break.

Functional airlaid sap paper is also under continuous development, and some diapers also have certain sterilization, skin care and other effects.

For example, Hengan Group has invented a functional core, which can endow the diaper with functions such as emollient, sterilization, and odor removal on the basis of improving the liquid absorption performance of the diaper. The bottom layer of the airlaid sap paper is a composite of the first water absorbing layer and the viscose layer, and the middle absorbing layer is the first hot air non-woven material layer, the second water absorbing layer, the second hot air non-woven material layer, the third water absorbing layer (from the bottom The surface layer is a hot air non-woven material sprayed with an antibacterial agent (the antibacterial agent is prepared from nano silver, green tea extract, honeysuckle extract, citrus extract, onion extract, etc.).

With the continuous improvement of people's requirements for diaper products such as thin, breathable, hygienic and non-irritating diapers, airlaid sap paper for diapers will develop in the direction of diversification and integration of functions, and the structure of airlaid sap paper is also constantly improving.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China