Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-02-16

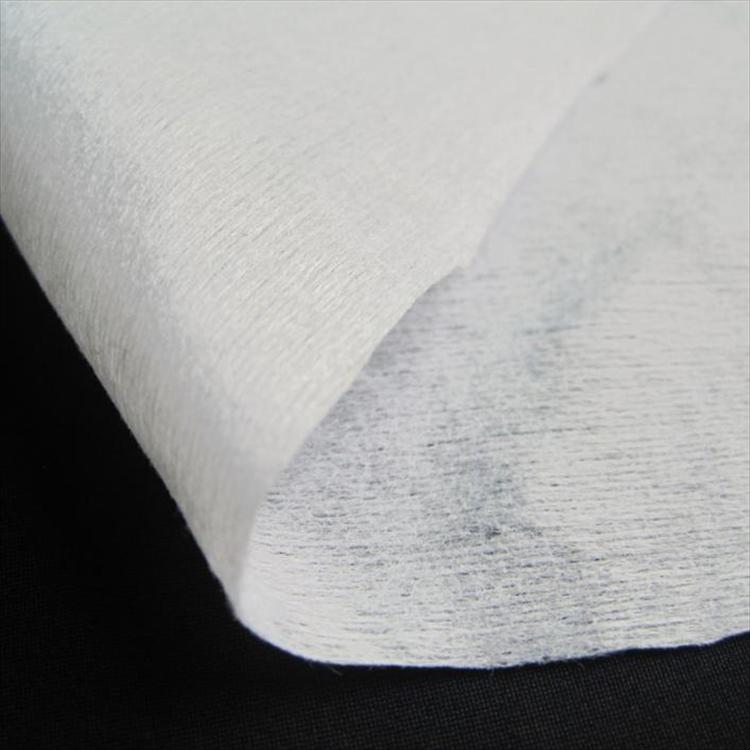

Spunlace process parameters have an important influence on the performance of Spunlace non woven fabric. This paper briefly explains the influence of process parameters on Spunlace non woven fabric from three aspects of fiber orientation, water needle and trawl curtain.

The mechanical properties of Spunlace non woven fabric, including tensile strength and bending stiffness, depend on the orientation of the fibers in the web. Fiber orientation is affected by web formation, entanglement and transfer. Because the cross-laid fibers are preferentially oriented in the cross-machine direction, the tensile strength of the web is stronger in the cross-machine direction than parallel to the machine direction.

High water pressure, few jets, and large jetting spacing will make Spunlace non woven fabric produce high-density area and low-density area structure, while low jet pressure, multiple needles, and small water needle spacing are easy to produce fiber webs with relatively uniform fiber distribution . The jet head water pressure also affects the fabric structure, with low water pressure creating a low density structure. Specific energy, the water jet energy per unit mass, is an independent factor affecting tensile strength, elongation, and pore size. Under the same specific energy, the spunlace fabrics produced by smaller jet pressure and more spunlace units exhibited different structures compared with multi-spunlace areas and lower water pressure. Compared with single-sided spunlace, the double-sided spunlace fabric showed better mechanical properties. Raising the specific energy above the critical value has been reported to have only a small effect on the tensile properties.

The carrier curtains that transport the web provide adequate support while facilitating the removal of entrapped water from the entanglement area. Water trapped on the surface of the web is a key problem with spunlace. It has been reported that the size of the mesh may have an impact on the actual fiber transfer mechanism. The tensile strength of spunlace nonwovens decreases as the mesh size decreases. Wire mesh curtains tend to squeeze the fibers in the web under high fluid pressure. Metal mesh curtains with tiny holes are ideal for improving the inclusion of short fibers in the web. The properties of nonwovens obtained from metal mesh support curtains and plastic mesh support mesh curtains are different. Increasing the conveying speed of the drape will reduce the tensile strength of the web.

The research in this paper helps to understand the potential impact of spunlace process parameter changes on the structure and performance of Spunlace non woven fabric, and also helps to formulate the process plan and optimize the performance of Spunlace non woven fabric.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China