Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-06

Many parents who have used nappies on their children would like to know what raw material diapers are made of, it's amazing how they absorb water and don't pick it up. Do you know what raw material diapers are made of?

As diapers are intimate hygiene products, their quality has received more attention. According to industry insiders, the threshold of China's diaper industry is high and the level of competition is relatively high. At present, large diaper manufacturers have advanced and reasonable equipment, process technology and product design, strict management of the production process and quality as well as raw material diapers' procurement, stable and reliable product quality, and it is mostly small enterprises that have problems. Experts say that the absorbent material of diapers in general is plant-based fibre material fluff pulp. To enhance the absorption effect and lock in moisture, a certain amount of high molecular absorbent resin needs to be added to the absorbent layer. As polymer absorbent resin is expensive, some companies have started to cut corners in this area, with some low-grade diapers even using crinkled toilet paper instead of absorbent material. Not long ago, the State Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) recently organised a national supervision and sampling inspection of the quality of diapers (including diapers/pads). This time a total of 49 enterprises in Beijing, Tianjin, Shanghai, Jiangsu, Zhejiang, Fujian, Guangdong and other seven provinces and municipalities directly under the Central Government produced 62 kinds of products, qualified 54 kinds, the product sampling rate of 87.1%. The sampling found that the main quality problems of nappies (including diapers/pads) were in two areas: First, microbiological indicators exceeded the standard. Four products in the sample exceeded the microbiological standards. One of the products had a measured value of 720 bacteria/g, which was 3.6 times higher than the standard limit. Secondly, the permeability performance was not qualified. Four kinds of products in this sampling failed to meet the standard requirements of permeability. Permeation performance is reflected by the amount of slip, back seepage and leakage indicators. The products that failed in the amount of slippage did not penetrate and absorb the liquid well; the products that failed in the amount of re-permeation absorbed the liquid and easily re-infiltrated, resulting in damp and uncomfortable skin for the user, affecting skin health.

Nappies contain high molecular absorbents, which can absorb 100 to 1000 times more than the diaper itself and will not be squeezed out again. The earliest nappies were mainly fleece pulp and therefore very thick. With the addition of polymer absorbents, the nappies became thinner and more comfortable. Therefore, the absorbency does not depend on the thickness, but even the opposite. Highly absorbent ones reduce the number of changes and do not disturb the sleeping baby; they also reduce the contact time between the urine and the skin, which reduces the chance of nappy rash.

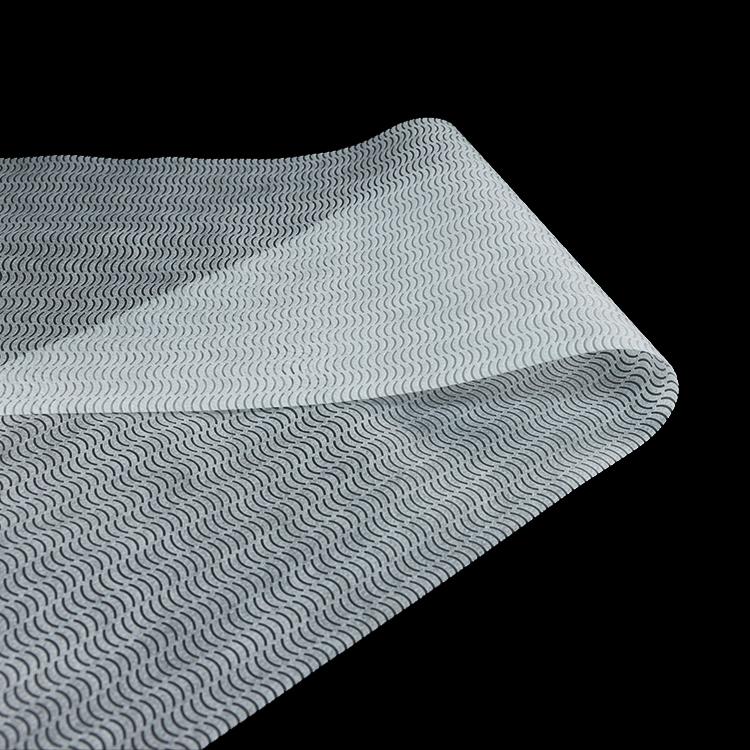

Nappies that are well ventilated and not stuffy for babies can easily lead to nappy rash if they are not well ventilated. Diapers that are not well ventilated can increase the local environmental temperature of the scrotum and may affect the development of the baby's testicles, especially for babies aged 0-1 years. The first thing that makes a good breathable nappy is that the inner material is naturally breathable and thinner. The most crucial thing is that the outer layer uses a breathable film, i.e. a thin plastic film with microscopic holes invisible to the naked eye, which is breathable but not water permeable.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China