Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-07

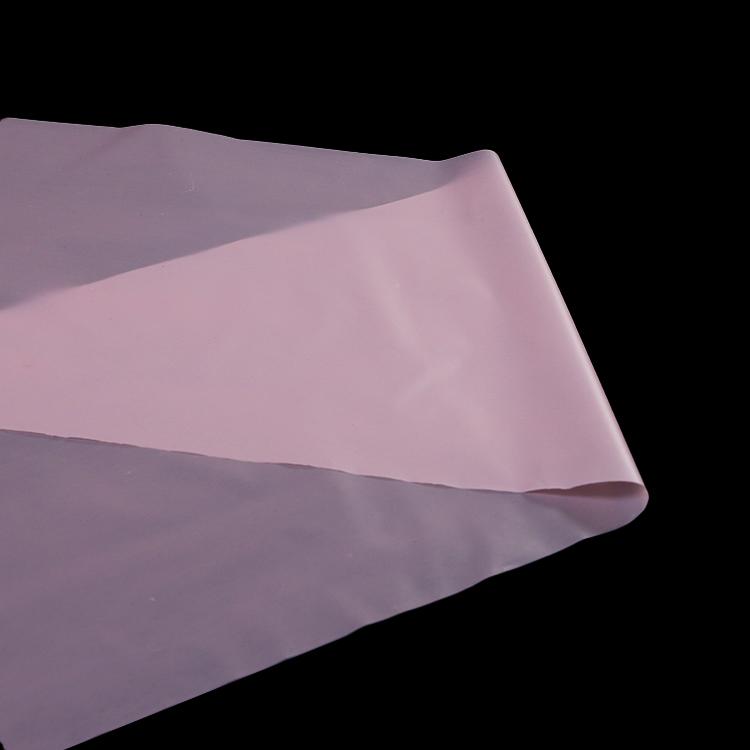

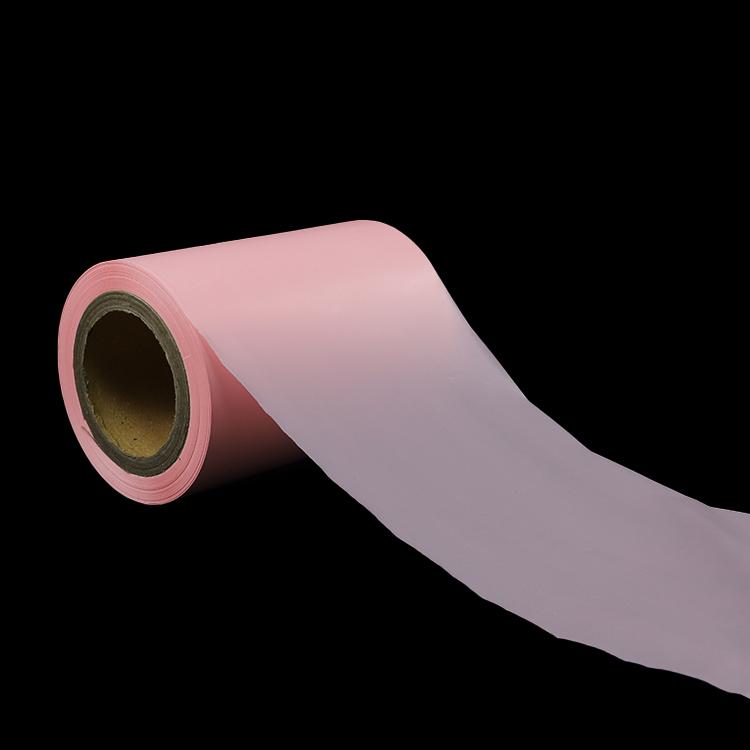

In the field of women's personal care products, PE film sheet has been widely used. At present, the vast majority of sanitary napkins and sanitary pads of international well-known high-end brands use PE film as the surface material. More and more domestic brands are using PE film sheet, and the amount of PE film is gradually increasing. According to statistics, the usage rate of PE film sheet in middle and high-end sanitary napkins has accounted for 80%, and the usage rate in ordinary wing sanitary napkins has also reached 40%, and it is still growing at a rate of 10%~15% per year. These are all formed because PE film has the characteristics and advantages that other surface materials cannot possess. This article introduces the solutions to the problems that occur in the actual use of PE film sheet from three aspects.

Sanitary napkins are currently using glue spray technology in large quantities.The use of glue spray solves the bonding and connection problems of various raw materials that sanitary napkins cannot solve only by mechanical methods. For PE films, it can solve PE film sheets and absorbent layers. Bonding problem. However, the quality of the glue and the glue spraying method directly affect the performance of the PE film sheet. Currently, dual-purpose adhesives and structural adhesives are mainly used on PE film sheets. If the amount of glue sprayed is too large, the glue will ooze out from the reverse side of the PE film, and there will be a sticky feeling on the PE film, which will affect the feel and permeability of the PE film. Poor quality glue will become hard and brittle after cooling, which also affects the feel and cannot achieve adhesion. In addition, an advanced glue spraying method must be used to spread the glue evenly on the PE film sheet to avoid local agglomeration. In addition, it is necessary to have a good grasp of the glue spraying temperature, so that the PE film sheet will not be deformed by high temperature, which will affect the appearance of the sanitary napkin.

With the extensive use of high-speed machine production lines, PE film sheets must have a certain unwinding tension and must be uniform and stable. Otherwise,the production efficiency of sanitary napkins will be greatly reduced and a large number of inferior products will be produced (this requires PE film sheet to have good horizontal and vertical tension and extensibility). This kind of good unwinding performance can only be guaranteed on advanced PE film equipment, and there is no condition for ordinary domestic machines to complete it.

Most of the forming of sanitary napkins and sanitary pads is done by hot pressing process, so it is necessary to master and control the hot pressing temperature and pressure of PE film sheet. If the temperature is too low or the pressure is too low, the sanitary napkin will not be able to be pressed against the peripheral seal and the diversion groove, and the sanitary napkin will be relatively loose, loose without a skeleton, and not crisp. If the temperature is too high or the pressure is too high, the surrounding seal of the sanitary napkin will become rigid, the diversion groove will be crushed, and the polymer absorber will leak out. Therefore, it is more reasonable to consider the temperature control and the use of glue spraying comprehensively.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China