Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-10-19

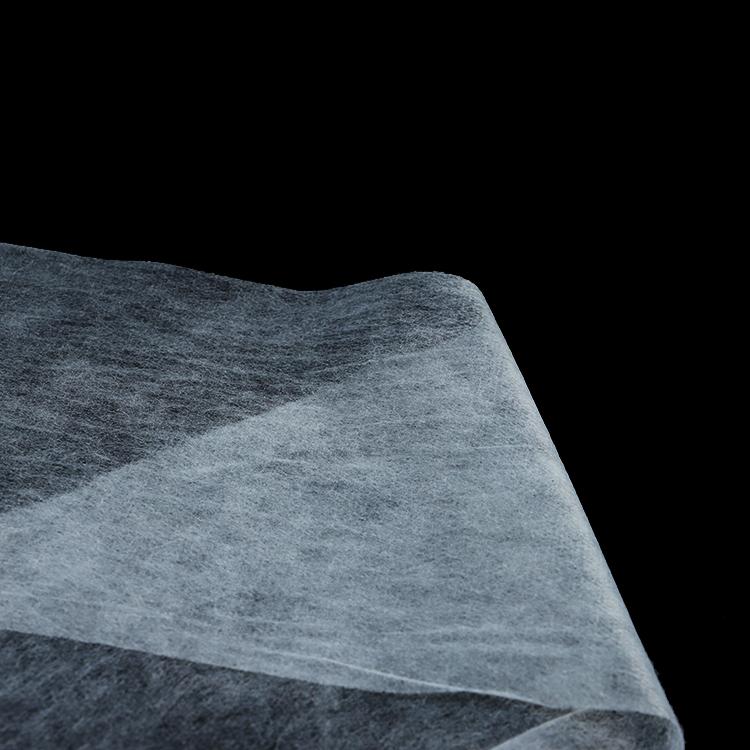

Spunbond nonwovens technology is a kind of nonwovens production technology with rapid development and high technical content in recent years, and it is one of the main process methods for processing nonwovens at present. This method is a one-step cloth nonwoven technology, not only has unique characteristics in terms of process route and equipment structure, but also the processed products have their own characteristics. This article briefly introduces the origin and development of PP spunbond technology. The spunbond method is a continuation of the commercial synthetic filament spinning process in the 1940s and 1950s. Its origin can be traced back to the 1940s. In the early 1950s, the US Naval Laboratory established a small melt extruder. The molten polymer is extruded from the spinneret hole to form fine filament fibers, and then blown to the web-forming curtain by hot air to bond the fibers into a web. This is the earliest spinning web technology, but due to the limitation of the technical level at that time, the technology could not be studied further.

With the development of chemical fiber technology, in the late 1950s, German Freudenberg company and American Dupont company began to study spunbond nonwoven technology. However, due to reasons such as high production cost and imperfect technology, this technology has been researched. The results were not replicated. In the 1960s, the American Du-pont company applied for a patent, and industrial production began in the mid-1960s. From the late 1960s to the early 1970s, the technology of spunbonded nonwovens was developed. The horizontal Venturi drafter has greatly improved the quality of spunbonded nonwovens, and the industrial production level has also been greatly improved. Later, Eisen Corporation of the United States applied meltblown technology to spunbond technology. Due to the use of a special structure of the stretcher, this made the PP spunbond technology have a greater development.

Due to the rapid progress of PP spunbond production technology, high growth rate, large production capacity, high quality, excellent performance, wide range of product applications, and strong market adaptability, coupled with the short production process of spunbond nonwovens and high production efficiency, It has the advantages of large-scale production, among which the strength and elongation of spunbonded nonwovens are better. At present, with the emergence of differentiated fiber spinning technologies such as melt-blown and spun-bonded multi-nozzle composite technology and two-component technology, it has brought broader application prospects to spun-bonded nonwovens technology, so in the 1990s In the future, spunbonded nonwovens will develop more rapidly and more extensively in terms of product use and technological advancement.

Understanding the origin and development of technology is beneficial to the further development of PP spunbond industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China