Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-03-16

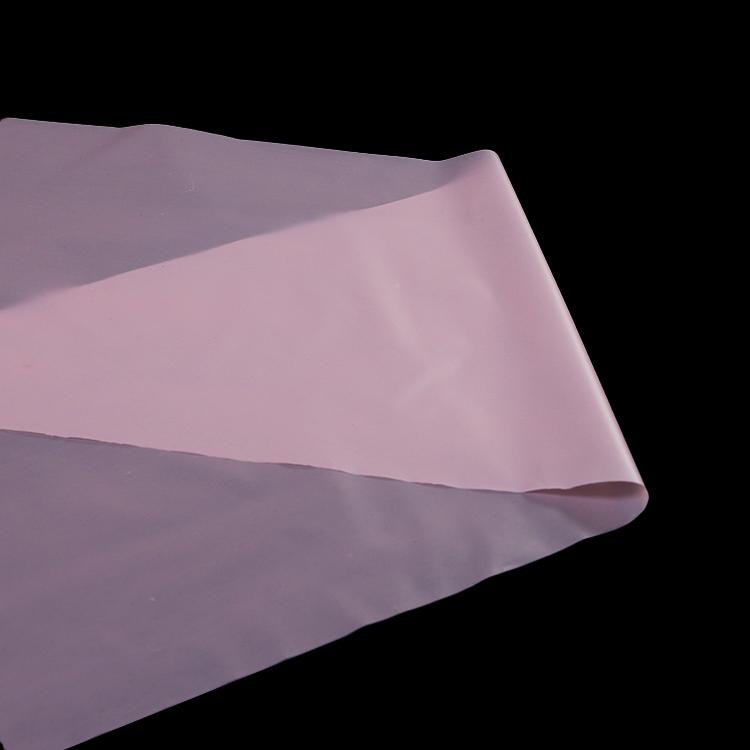

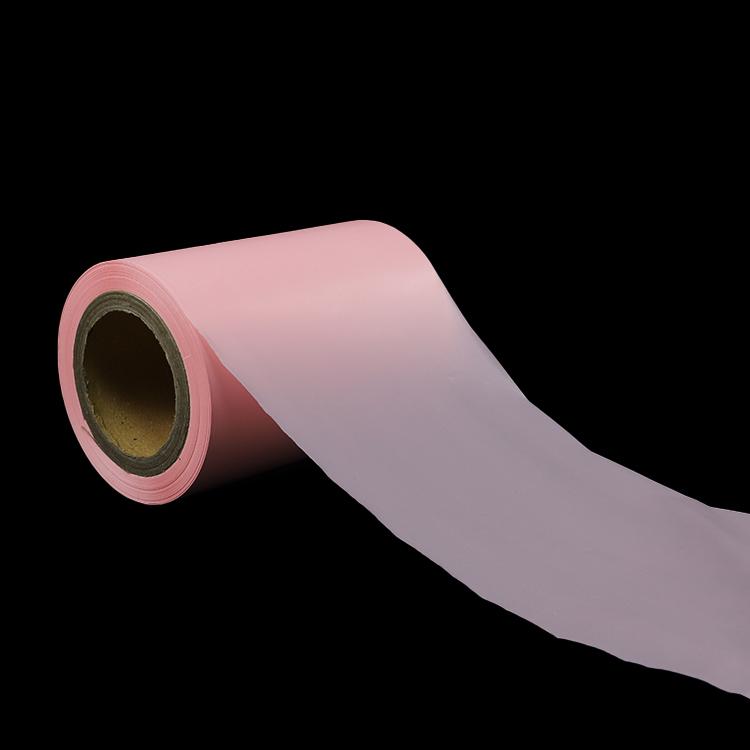

Polyolefin PE Breathable film backsheet uses calcium carbonate and other inorganic fillers as porogens to fill polyolefin to make a masterbatch, and then make a film by calendering or casting, blow molding, and finally form a breathable backsheet by unidirectional or bidirectional stretching. film. It is a polymer waterproof and breathable material, which is mostly used in products such as sanitary napkins, diapers and protective clothing. With the spread of the new coronavirus around the world, there is a greater demand for medical supplies around the world. As the demand for breathable membrane materials continues to grow, it has stimulated the growth in demand for calcium carbonate used in breathable membranes.

The performance requirements of PE Breathable film backsheet include: good mechanical strength, easy to stretch vertically and horizontally; excellent hydrophobicity; relatively uniform porosity and air permeability; special morphological structure, etc. This places specific requirements on the calcium carbonate used.

This has to do with the way the ore is processed. Before the ore is used, it is recommended to analyze the composition of each piece of ore. If the conditions are met, the ore can be analyzed by XRD to predict the long-term stability of the ore.

PE Breathable film backsheet does not break. According to the thickness requirements of the membrane, the secondary and tertiary classifications are carried out to screen out large particles.

According to the thickness of the film, determine the particle size distribution range of the powder. Calcium carbonate cannot exceed the thickness of the film, if it exceeds, it will cause holes in the breathable film when it is stretched vertically and horizontally.

One of the keys to increasing air permeability is to disperse calcium carbonate particles uniformly in the membrane, which can ensure the strength of the membrane after stretching and obtain a higher porosity. If the calcium powder is poorly dispersed in the membrane and the fluidity is too poor, it will cause holes in the downstream membrane and reduce production efficiency. Special particle size distribution control, equipped with suitable grinding, classifying and activation equipment. Large particles are screened out, and the content of fine powder is not too high.

For a long time, the main reason why domestic calcium carbonate for breathable membranes has been restricted by foreign countries is: on the one hand, the coating equipment cannot reach it, and on the other hand, the coating additives cannot reach it. Domestic enterprises have done a lot of work on this in recent years. It is reported that the nail plate activation machine developed by Dongguan Wuquan Machinery Co., Ltd. has an average activation degree of calcium carbonate for modified breathable membranes as high as 99.8%. Excellent stability, low volatile substances, selection of suitable activation aids.

The low water absorption of heavy calcium powder and the high water content of calcium carbonate can easily lead to water marks in the downstream casting film. When it is more serious, it will lead to the increase of agglomerates in the molten state, resulting in network blocking, uneven discharge, perforation and other phenomena.

On the one hand, low oil absorption means less agglomeration; on the other hand, low oil absorption can avoid adding too much low-molecular additives during granulation, because the traction speed of more than 200 meters per minute must have high traction speed during the production of breathable membranes. Melt strength and tensile strength of the film, adding too many additives will reduce the melt strength and tensile strength of PE Breathable film backsheet.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China