Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-05-26

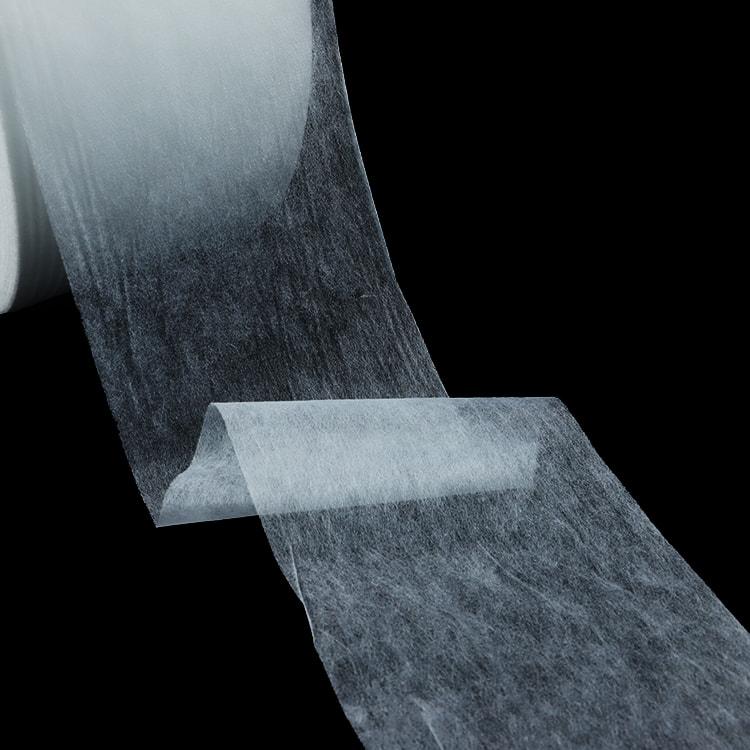

Due to different production technologies, product prices and application fields, currently the commonly used raw materials for spunbond fabrics are mainly polypropylene PP, polyester PET and polyamide PA6 or PA66.

This is currently the most widely used resin in spunbond fabrics. It is generally rheology-controlled, with high uniformity and high quality. Main indicators: Melt index ≥ 27, molecular weight distribution 180000~300000, ash content ~<200mg/kg, isotacticity ≥95. Because PP has the advantages of high strength, low melting point, good processing performance, good chemical resistance, low density and low price, it is widely used in the fields of women's sanitary napkins, baby diapers, adult diapers, agricultural harvest cloth and furniture packaging materials. application.

Main indicators: intrinsic viscosity 0.61~0.66 dL/g, molecular weight distribution 19000~21000, ash content ≤0.07%, moisture content ≤0.4%. PET has high strength and comprehensive performance indicators, and its application in the spunbond process is second only to PP. Since the PET chips used in most production lines must be dried in advance, the unit energy consumption is higher than that of PP products, and the price of the chips themselves is also high, so the cost and price of PET spunbond fabrics are higher than that of PP. high product. According to the different reinforcement methods, the slice raw material can be homopolymer or copolymer. Generally, a single type of homopolymer is used for mechanical reinforcement; some low-melting copolyesters can be used for thermal bonding reinforcement to reduce energy consumption. When producing two-component products, the core component is also made of homopolyester, while the outer layer is mostly made of copolyester or polyolefin. Because polyester spunbonded fabric has obvious advantages in strength and weather resistance, it is widely used in agriculture, packaging, geotechnical construction, roof waterproof substrate and other fields.

Main indicators: intrinsic viscosity 2.6~2.9 dL/g, molecular weight distribution 16000~22000, monomer content ≤ 2.0%, moisture content ≤ 0.07%. Polyamide has good strength, wear resistance, dyeability and moisture absorption. Due to its higher price, this raw material is used less.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China