Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-05-30

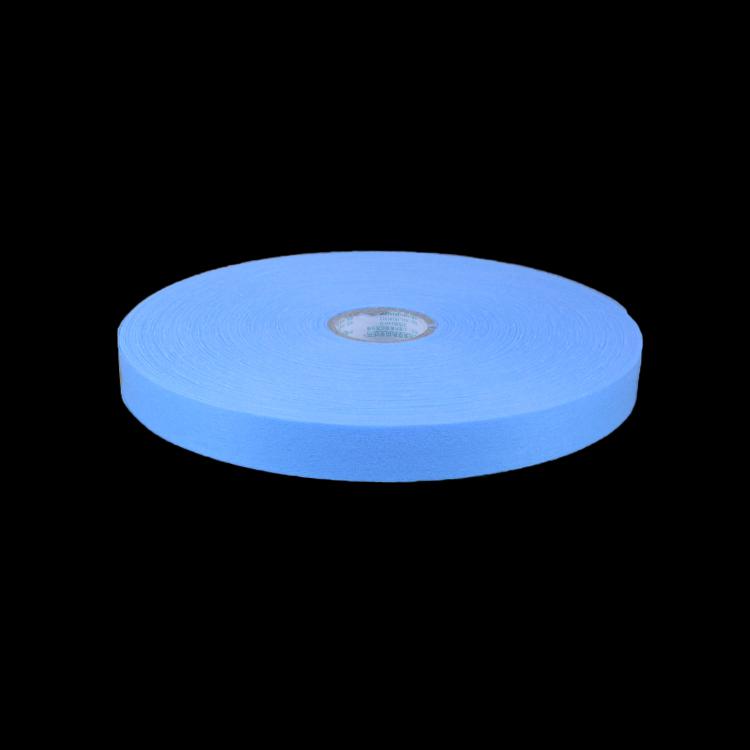

Acquisition Distribution Layer (ADL) is an essential component in the production of disposable diapers. It is a non-woven material sandwiched between the absorbent core and the top sheet, which helps to distribute the liquid evenly and quickly to enhance the performance of the diaper.

ADL is made up of thermoplastic fibers, which provide excellent wicking and distribution properties. The material is designed to improve the performance of disposable diapers by allowing faster absorption of urine and ensuring that the baby's skin remains dry and comfortable. ADL also helps to prevent leaks by distributing the liquid evenly throughout the absorbent core.

The use of ADL in diapers provides several benefits. First, it allows for better absorption of urine, keeping the baby's skin dry and comfortable. Second, it helps to prevent leakage by distributing the liquid evenly throughout the diaper. Third, it reduces the risk of skin irritation and rash, as the moisture is kept away from the baby's skin. Finally, ADL ensures that the diaper remains in place, even during active playtime.

ADL is made using a special process where thermoplastic fibers are bonded together using heat and pressure. The fibers are arranged in a specific pattern to allow for maximum liquid dispersion. Once the material is produced, it is cut into the required sizes and shapes before being inserted into the diaper production line.

In conclusion, Acquisition Distribution Layer (ADL) is an important component in disposable diaper production. It plays a crucial role in absorbing and distributing urine, keeping the baby's skin dry and comfortable. By preventing leaks and reducing the risk of skin irritation, ADL helps to ensure that babies remain happy and healthy. Its manufacturing process involves bonding thermoplastic fibers together to create a material with excellent wicking and distribution properties.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China