Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-06-07

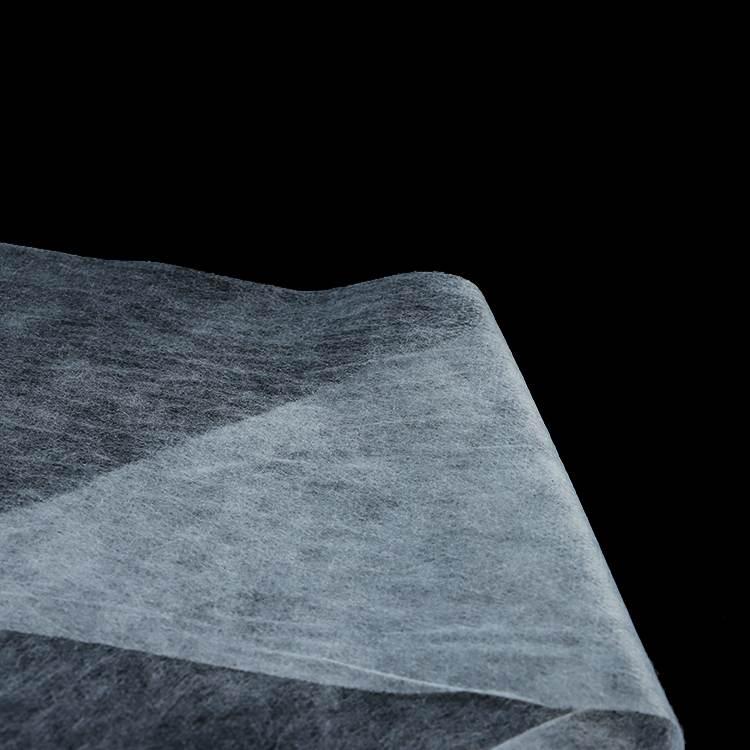

As one of the most important raw materials for disposable diapers, meltblown non woven fabric has become a hot topic in recent years. This article will discuss the characteristics and applications of meltblown non woven fabric in the diaper industry.

Meltblown non woven fabric is a type of non-woven material made from high-quality polypropylene. The production process involves melting and extruding the polymer through small nozzles to create continuous filaments. These filaments are then cooled and stretched into a web-like structure by high-speed hot air or other special methods.

There are several advantages of using meltblown non woven fabric in diapers. Firstly, meltblown non woven fabric has excellent absorption and retention properties, which can effectively reduce leakage and ensure dryness. Secondly, it has a soft and gentle texture, which provides comfort and protection for babies' sensitive skin. Thirdly, it is highly breathable and can promote air circulation, reducing the risk of diaper rash.

Meltblown non woven fabric is used in various parts of disposable diapers, such as the absorbent core, top sheet and back sheet. In the absorbent core, meltblown non woven fabric is mixed with wood pulp to form a fluffy structure that can quickly absorb and lock away moisture. In the top sheet and back sheet, meltblown non woven fabric is used to enhance the softness and breathability of the diapers.

In conclusion, meltblown non woven fabric plays an important role in improving the performance of disposable diapers. Its unique properties make it an ideal choice for use in the diaper industry. As the demand for high-quality diapers continues to grow, the application of meltblown non woven fabric is expected to become more widespread.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China