Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-06-07

Introduction:

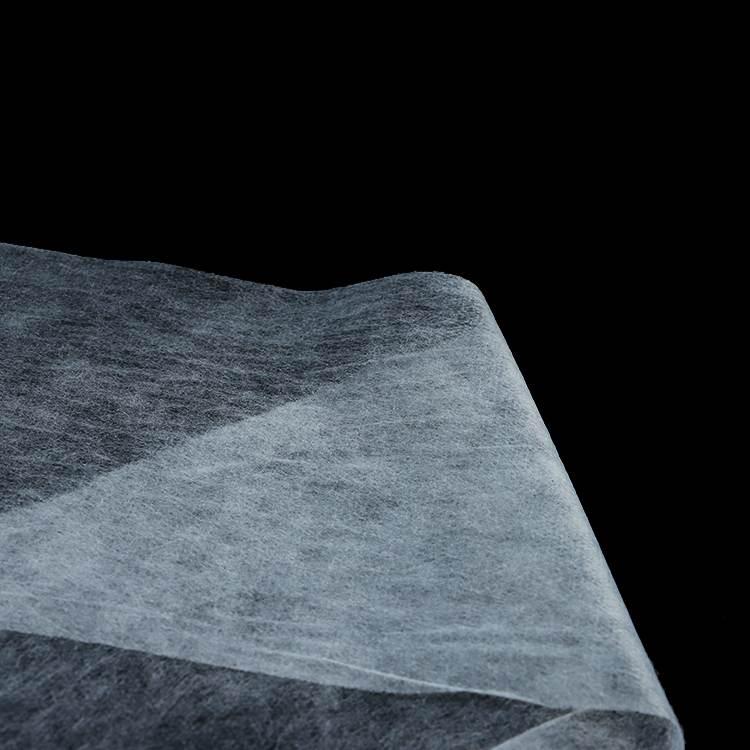

Non woven fabrics are widely used in various industries, including the production of diapers for babies and adults. Non woven fabric waterproofing is an essential feature in these products, as it helps prevent leakage and keeps the skin dry and comfortable. In this article, we will discuss how non woven fabric waterproofing works and its benefits for the diaper industry.Non woven fabric waterproofing refers to the ability of non woven fabrics to resist the penetration of water or other liquids. This is achieved by using a special coating or treatment on the fabric that creates a barrier against moisture. The coating can be made from various materials, including polymers, resins, or wax. The treatment can be applied to the fabric using different techniques such as extrusion, lamination, or printing. The result is a fabric that repels liquids and maintains a dry surface.

There are several advantages to using non woven fabric waterproofing in diapers. Firstly, it prevents leakage, which is crucial for the comfort and hygiene of the wearer. Secondly, it keeps the skin dry, reducing the risk of diaper rash and other skin irritations. Thirdly, it enhances the absorbent performance of the diaper by preventing the liquid from escaping from the absorbent core. Fourthly, it improves the overall durability and strength of the diaper, ensuring it can withstand wear and tear, and maintain its shape and integrity.

Conclusion:

In conclusion, non woven fabric waterproofing is a critical feature in the production of diapers for babies and adults. It provides several benefits, including leakage prevention, skin dryness, absorbent performance enhancement, durability, and strength. The manufacturing process involves specialized techniques and materials that require strict quality control to ensure consistent and reliable performance. Non woven fabric waterproofing has revolutionized the diaper industry, making it possible to produce high-quality, comfortable, and reliable products that meet the needs of consumers worldwide.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China