Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-05

Introduction:

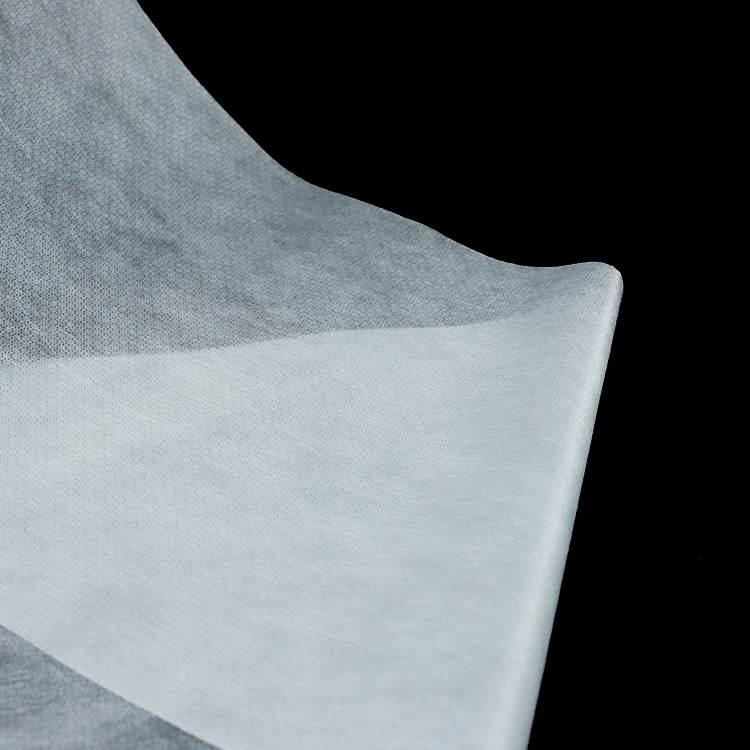

Hydrophobic SMMS non-woven fabric is a specialized material used in the manufacturing of paper diapers. Its unique properties make it an ideal choice for diaper production and have revolutionized the diaper industry. In this article, we will explore the benefits, manufacture, and applications of hydrophobic SMMS non-woven fabric in the production of paper diapers.Hydrophobic SMMS non-woven fabric is a unique material that possesses several advantages over traditional materials like cotton or woven fabrics. The fabric is made from four layers of synthetic fibers, each with its own specific function. The outer two layers are made of spunbonded polypropylene, which gives the material its strength and durability. The inner two layers are made of melt-blown polypropylene microfibers, which provide the fabric's filtration and absorption capabilities. One of the most significant advantages of hydrophobic SMMS non-woven fabric is its ability to repel water. Due to its structure, the fabric can effectively prevent liquid from penetrating through it, making it an ideal choice for diaper production. Additionally, the fabric is soft to the touch, comfortable for babies to wear, and has excellent breathability, allowing air to circulate freely, keeping the baby's skin dry and free of irritation.

The manufacturing process of hydrophobic SMMS non-woven fabric involves several intricate steps. First, the polypropylene resin is melted and extruded into several fine filaments. These filaments then undergo spinning, where they are directed onto a slowly rotating drum, forming a web-like material. This material is then passed through a series of rollers, where the layers are bonded together through heat and pressure. After bonding, the fabric is treated with a hydrophobic agent that renders the material water repellent. This treatment involves applying a silicone-based chemical through a spray or immersion process. The fabric is then passed through a curing oven, where the chemical is dried onto the surface, creating a water-resistant barrier.

Conclusion:

Hydrophobic SMMS non-woven fabric is a versatile material with a wide range of applications. Its unique properties make it an ideal choice for diaper production, where its water-repellent and breathable properties help keep babies dry and comfortable. The manufacturing process of hydrophobic SMMS non-woven fabric is intricate but yields a superior product that is strong, durable, and effective. As technology continues to evolve, we can expect new and innovative uses for hydrophobic SMMS non-woven fabric, making it an indispensable material in the manufacturing industry.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China