Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-21

Exploring the Applications of Raw Materials in Diaper Manufacturing

Diapers are a necessity for infants and young children, providing comfort and convenience for both parents and babies. The manufacturing process of diapers involves the use of various raw materials, each with its unique properties and functions. In this article, we will explore the applications of these raw materials in diaper manufacturing, highlighting their importance in creating high-quality and effective diapers.

The absorbent core is the heart of a diaper, responsible for absorbing and locking away moisture. Superabsorbent polymers (SAP) are commonly used in the manufacturing of diapers due to their exceptional absorbency. These polymers have the ability to absorb and retain large amounts of liquid, transforming it into a gel-like substance. This not only keeps the baby's skin dry, but also prevents leakage. SAPs are typically combined with fluff pulp, a soft and fluffy material made from wood fibers. The fluff pulp acts as a supplementary absorbent, enhancing the overall absorbency of the diaper while maintaining its shape and form.

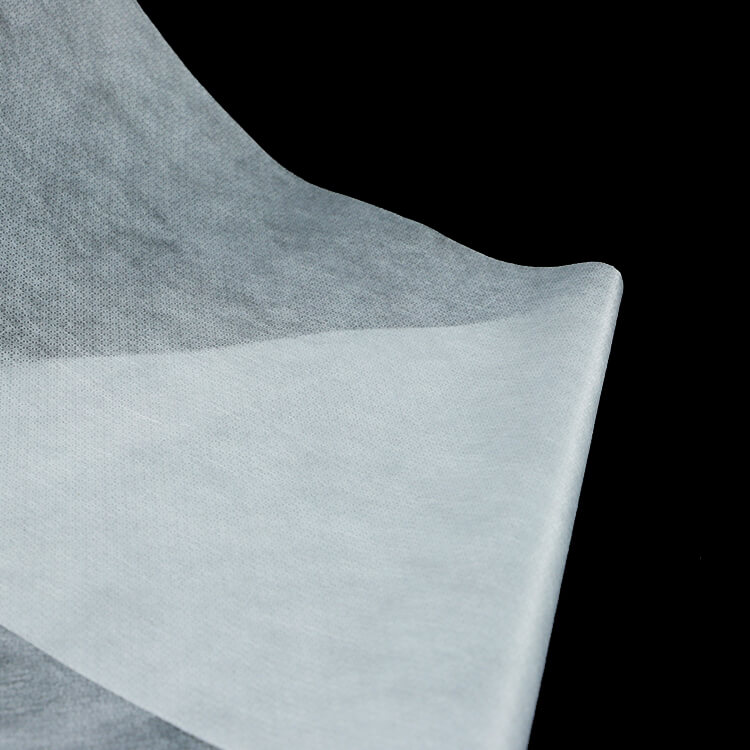

The outer layer of a diaper serves as a barrier, preventing leakage and ensuring that the baby's clothes and surroundings remain dry. Nonwoven fabrics are commonly used for this purpose. These fabrics are made by bonding or interlocking fibers together, creating a porous and breathable material. Nonwoven fabrics provide excellent liquid repellency while allowing air circulation, keeping the baby's skin comfortable and preventing diaper rash. In addition to nonwoven fabrics, some diapers also incorporate a waterproof layer made of polyethylene film to further enhance leak protection.

Proper fitting is crucial for a diaper's functionality and comfort. Fastening and elastic materials play a vital role in ensuring that the diaper stays in place and fits snugly around the baby's waist and legs. Hook-and-loop fasteners, commonly known as Velcro, are widely used as closure systems in diapers. These fasteners are highly adjustable and secure, allowing for easy diaper changes while providing a secure fit. Elastic materials, such as spandex or Lycra, are used in the leg cuffs and waistbands of diapers to provide a stretchable and comfortable fit. They ensure that the diaper remains in position and prevents any leaks.

The applications of raw materials in diaper manufacturing are essential for producing high-quality diapers that provide comfort, dryness, and leakage protection. From the absorbent core materials that efficiently lock away moisture, to the outer layer materials that keep the baby's skin dry, and the fastening and elastic materials that ensure a proper fit, each component plays a vital role. Continued research and development in raw materials will further improve the performance and sustainability of diapers, benefiting both babies and the environment.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China