Author:Baby & Adult Diaper Materials FROM:Diaper Materials Manufacturer TIME:2023-07-25

Unveiling the Power of SMMS Non Woven in Diaper Production

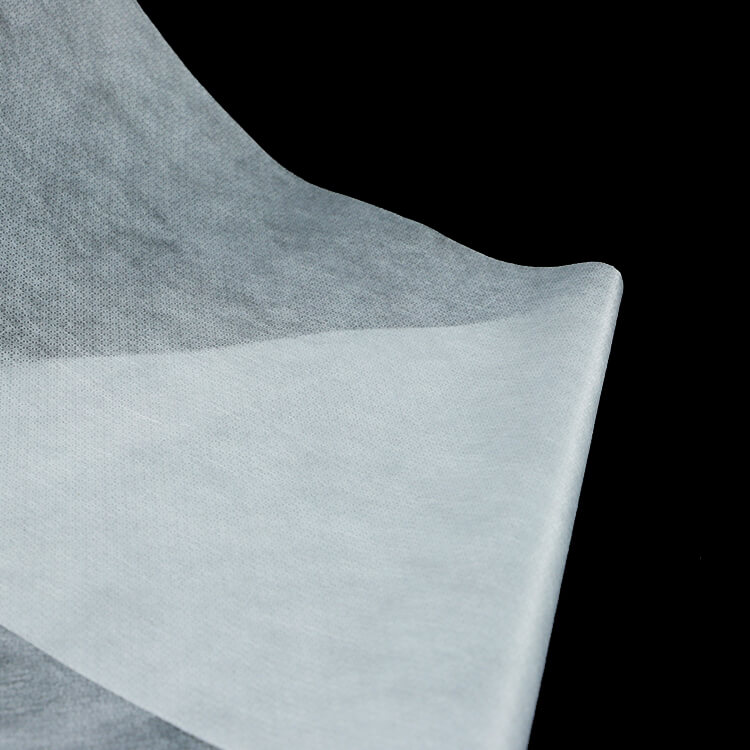

In recent years, the diaper industry has witnessed remarkable advancements in technology and materials. One such innovation that has revolutionized the manufacturing process is the use of SMMS non woven. This article aims to explore the power of SMMS non woven in diaper production and its impact on the overall quality, performance, and comfort of diapers.

One of the key benefits of utilizing SMMS non woven in diaper production is its enhanced absorbency. The unique structure of this material allows for rapid liquid absorption, reducing the chances of leakage and providing better protection for the wearer. The combination of spunbond and meltblown layers in SMMS non woven creates a high-density barrier, preventing any liquid from seeping through the diaper, even under pressure. This not only ensures the comfort of the baby but also provides peace of mind to parents.

Furthermore, the uniform distribution of fibers in SMMS non woven promotes efficient liquid retention, minimizing the risk of rewetting. This is particularly crucial for overnight usage when babies tend to produce higher volumes of urine. With SMMS non woven, diaper manufacturers can offer products with extended dryness, keeping babies comfortable and reducing the frequency of diaper changes.

Baby's delicate skin requires utmost care and protection. SMMS non woven excels in providing exceptional softness and breathability, making it an ideal choice for diaper production. The combination of spunbond and meltblown layers creates a fabric that is gentle on the skin while allowing for adequate airflow.

The smooth surface of SMMS non woven minimizes friction, reducing the risk of irritation and rashes. Additionally, the breathable nature of this material helps to regulate temperature and moisture, preventing discomfort and maintaining a dry environment for the baby's skin. By incorporating SMMS non woven in diapers, manufacturers can ensure that babies stay dry, cool, and comfortable throughout the day.

Aside from its performance benefits, SMMS non woven also offers advantages in terms of manufacturing efficiency and cost-effectiveness. The lightweight nature of this material allows for easy handling and processing during the production process, resulting in increased productivity for diaper manufacturers.

Moreover, SMMS non woven is highly durable and exhibits excellent tensile strength, ensuring the integrity of the diaper structure. This reduces the likelihood of product defects and increases overall efficiency on the production line. The longevity and robustness of SMMS non woven also contribute to its cost-effectiveness, as it reduces the frequency of diaper replacements and returns due to manufacturing issues.

Additionally, SMMS non woven is produced using a combination of polypropylene materials, which are readily available and cost-effective. This makes it a viable choice for diaper manufacturers looking to optimize their production costs without compromising on quality.

The utilization of SMMS non woven in diaper production has undoubtedly transformed the industry by enhancing absorbency, leakage protection, softness, breathability, manufacturing efficiency, and cost-effectiveness. This innovative material has proven to be a game-changer, allowing diaper manufacturers to offer high-quality products that prioritize the comfort and well-being of babies. As technology continues to evolve, we can expect further advancements in the utilization of SMMS non woven, leading to even more innovative and superior diapers in the future.

Email: info@whldiapernonwoven.com

Email: info@whldiapernonwoven.com

MP/WhatsApp: +86-13599937366

MP/WhatsApp: +86-13599937366

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China

Manufacturer Address:Room 1105B, Bld M1, Manhattan, Yulongwan, Shimao, Shuanglong Road, Meiling Street, Jinjiang, Fujian, China